Software release 3.5

We are proud to announce our new series of HD2 cameras, featuring both structured light and laser triangulation technologies. These advanced cameras offer larger fields of view, greater accuracy, and higher resolution with respect to the previous models.

Our camera selection has never been more comprehensive! Continue reading to discover the impressive capabilities of our expanded lineup.

Second-generation extended camera lineup

Pickit 3.5 introduces new cameras that extend the second-generation of certified cameras. This updated portfolio addresses a wider range of applications while delivering significant improvements in both performance and reliability. All cameras utilize Ethernet as their communication technology, and both technologies lineups cover fields of view ranging from small boxes to multiple Euro Pallets (EPAL).

Note

Starting with Pickit 3.4, we have updated the naming convention for our cameras. For instance, what was previously known as the XL-HD2 is now referred to as XL-HD2-C1600. This change allows us to expand our lineup allowing multiple cameras on the same range.

We offer three families of HD cameras: M-HD2, L-HD2, and XL-HD2, each featuring one or more models. The full name of each camera will be a combination of its range (e.g., M-HD2) and the vendor code (like Zivid M70), resulting in a name such as M-HD2-M70.

Structured light technology

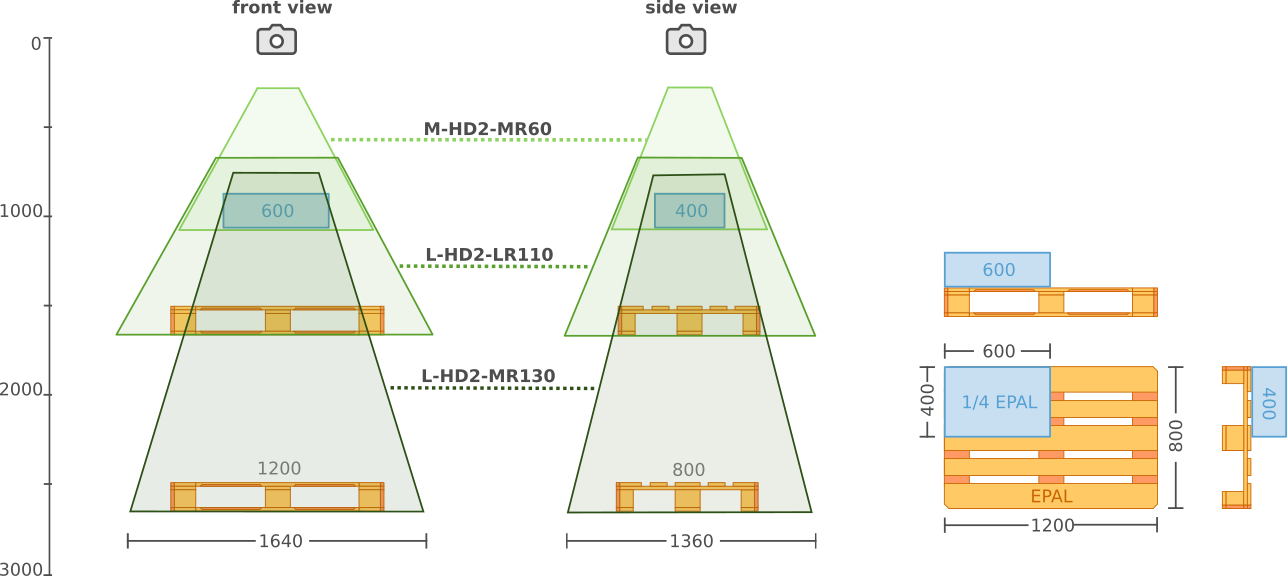

Our new structured light camera lineup includes the M-HD2-MR60, the L-HD2-LR110, and the L-HD2-MR130. These three cameras represent the latest generation of Zivid technology and will replace the previous M-HD2-M70 (M-HD2) and L-HD2-M130 (L-HD2) models.

The new L-HD2-LR110, with its wide field of view and close focus capability, is particularly well-suited for robot-mounted applications.

The M-HD2-MR60 features a field of view comparable to the previous M-HD2-M70, but compared to it, delivers a higher resolution point cloud (1.2Mpx vs 0.5Mpx) and superior performance with shiny parts.

Finally, the L-HD2-MR130 maintains the same field of view as its predecessor L-HD2-M130 (L-HD2) while achieving faster capture times.

Below is an overview of the fields of view of each structured light camera. You can explore them in more detail in the datasheet of each camera, or using our interactive camera selector.

M-HD2-MR60 |

L-HD2-LR110 |

L-HD2-MR130 |

|

|---|---|---|---|

Performance |

|||

1-2 |

2-4 |

2-6 |

|

up to 0.5 |

up to 1.0 |

up to 1.0 |

|

Detection distance [mm] |

300-1100 |

700-1700 |

800-2700 |

Camera mount |

|||

Fixed |

✓ |

✓ |

✓ |

On-robot |

✓ |

✓ |

✓ |

Laser triangulation technology

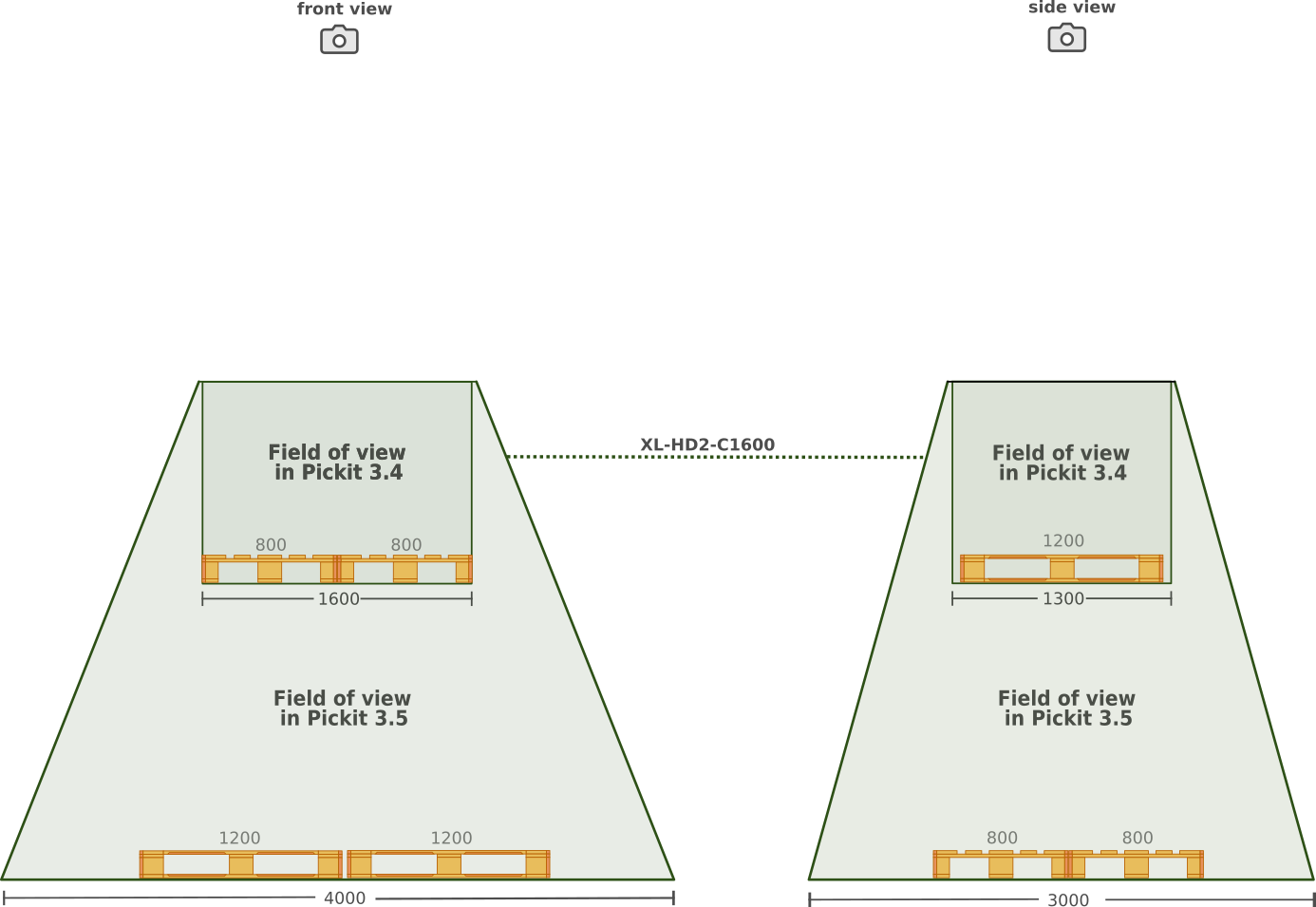

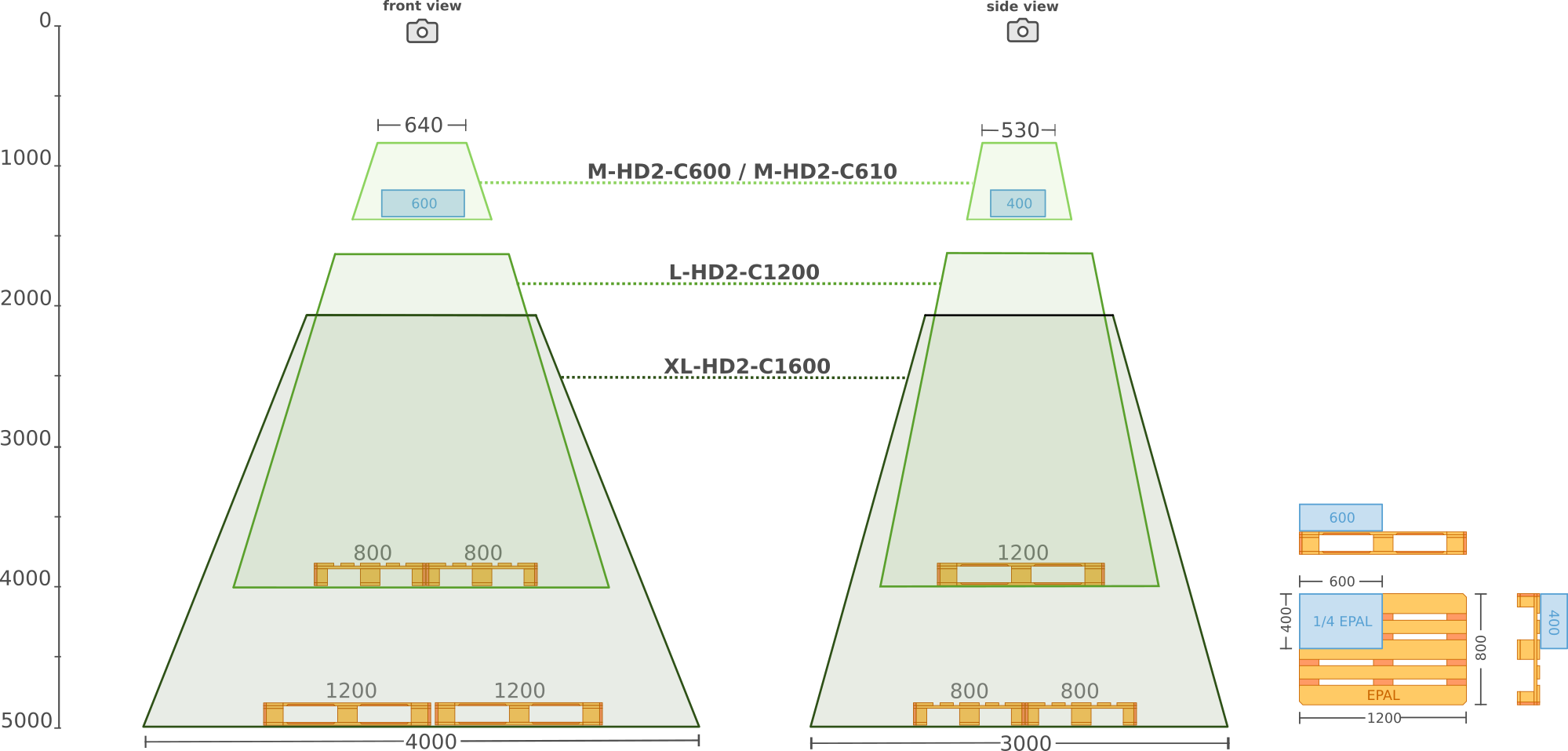

In Pickit 3.4, we introduced the XL-HD2-C1600 (XL-HD2), which utilizes laser triangulation for reconstructing the 3D point cloud. With this release, we’re adding three new cameras to the lineup: the M-HD2-C600, M-HD2-C610, and L-HD2-C1200.

These four cameras, manufactured by Visionerf, offer several important improvements:

The field of view is approximately three times larger, making use of the entire pyramid instead of just a box. In the previous release the XL-HD2-C1600 could scan two EPALs tightly, whereas now it can comfortably cover four!

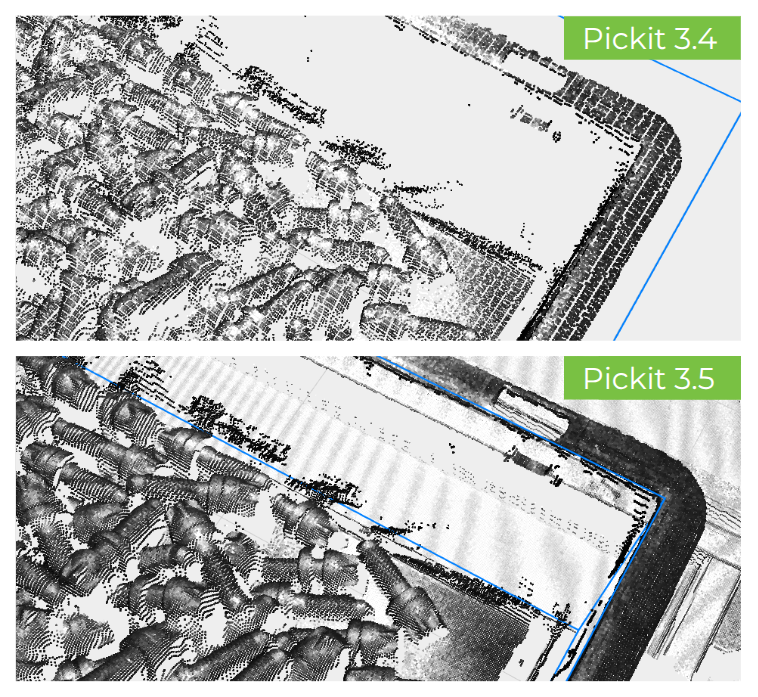

Accuracy has been significantly increased: for the XL-HD2-C1600, it has improved from 2-4mm in version 3.4 to 1.5-3mm in this release.

The point cloud offers higher resolution with fewer missing points:

Below is an overview of the fields of view of each laser triangulation camera. You can explore them in more detail in the datasheet of each camera, or using our interactive camera selector.

M-HD2-C600 |

M-HD2-C610 |

L-HD2-C1200 |

XL-HD2-C1600 |

|

|---|---|---|---|---|

Performance |

||||

0.5-1.5 |

1-2.5 |

1-2.5 |

1.5-3 |

|

up to 0.5 |

up to 0.5 |

up to 0.75 |

up to 1.0 |

|

Detection distance [mm] |

800-1350 |

800-1350 |

1600-4000 |

2040-5000 |

Camera mount |

||||

Fixed |

✓ |

✓ |

✓ |

|

On-robot |

✓ |

|||

Warning

First-generation SD cameras are still supported in Pickit 3.5, although no longer offered. They will no longer be supported in future versions of Pickit.

First-generation HD cameras are no longer supported in Pickit 3.5. However, Pickit 3.4 will continue to be maintained during the lifetime of Pickit 3.5 to support existing customers using these cameras.

Get the update now

This upgrade is incremental, and requires Pickit to be at version 3.3. If you have an older version, please upgrade first to 3.3 before moving to 3.5. If you are interested in upgrading and trying out Pickit 3.5, check out how you can upgrade your system.