Warning

You are reading the documentation for an older Pickit release (3.3). Documentation for the latest release (4.0) can be found here.

Maximum robot flange tilt

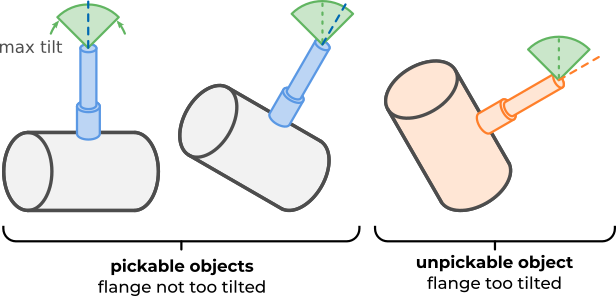

This setting rejects picks where the robot flange would tilt too much. Such picks are more likely to result in unreachable robot motions. Tilt is measured between the ROI vertical direction and the robot tool flange Z-axis (or pick point Z-axis, if no tool has been assigned to the pick point).

As seen in the image below, if an object is tilted more than the specified angle, it will be labeled as unpickable. In the Pickit web interface, unpickable objects are displayed orange in the Objects view and the Objects table.

Zero robot flange tilt

A special case worthy of mention is that of zero allowed flange tilt, which is common when working with four-axis robots and applications like depalletizing. As opposed to robots with six (or more) axes, their end-effector cannot tilt with respect to the vertical. In such cases, the recommendation is to:

Enforce picks pointing up (zero flange tilt), where the up direction is defined by the ROI Z-axis.

Use a robot tool that can tolerate some tilt in XY, to still allow picking slightly tilted objects.

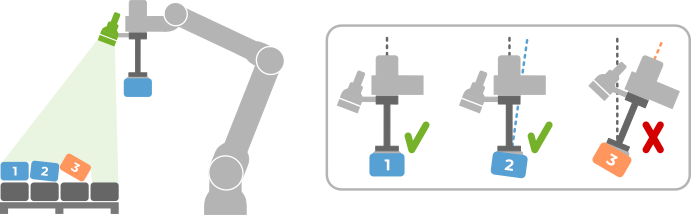

In the example below, parts 1 and 2 can be picked with a 4-axis robot and a tool that tolerates some tilt. Note how tool tilt is used to pick part 2, which is slightly tilted, yet the robot flange remains untilted. Part 3 is too tilted for a 4-axis robot with this tool, and is labeled as unpickable.