Warning

You are reading the documentation for an older Pickit release (3.2). Documentation for the latest release (4.0) can be found here.

Tool modeling best practices

The following are a number of best practices that optimize your robot tool model such that collision prevention is both correct and efficient.

Slightly larger tool model

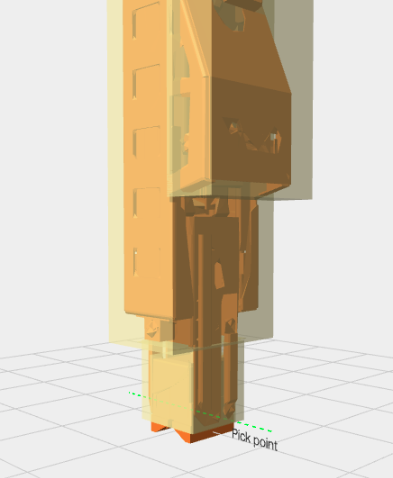

It is recommended that the robot tool model is slightly larger than the actual tool, to have a safety margin when performing robot motions. If the model is too large (too conservative), objects will be labeled as unpickable even if they could be picked without collision. Conversely, if the model is smaller than the actual tool, unpickable objects might be labeled as pickable and the robot will collide when picking them. The example below shows an overlay of the real tool geometry (dark orange) and a slightly larger robot tool model (semi-transparent orange).

Don’t model the last millimeters of the tool tip

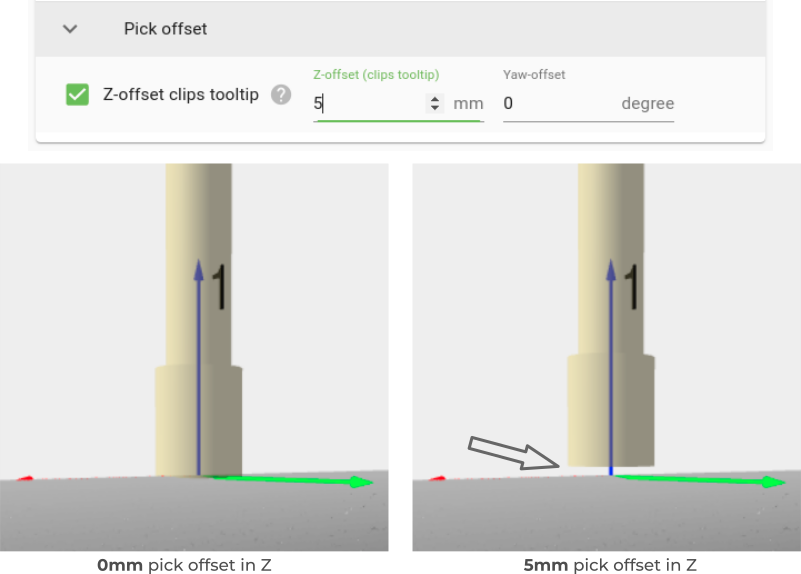

When modeling the robot tool, it’s often recommended to not model the last millimeters of the tool tip to prevent false-positive collision detections. This applies to flexible tool tips like suction cups, where it is acceptable that the flexible bellows collide with the object to pick. but also applies to rigid tools like magnets and gripper fingers.

A value of 5mm works well for most applications, and is used in the below example:

When using generic tool models, set the

Pick offset > Z-offset. Make sure to enable theZ-offset clips tooltipcheckbox to only clip the tool and not displace the entire tool up with the offset.When using CAD-based models, set the

CAD modifiers > Bottom clip offset.

Simplify your CAD tool model

When using CAD-based tool models, collision prevention checks can be sped up by following these recommendations when preparing your CAD file:

Remove all non-visible geometry such as inner walls. They slow down collision checks without adding any value.

Reduce the complexity of the CAD geometry. A typical model should not exceed a few thousand faces.

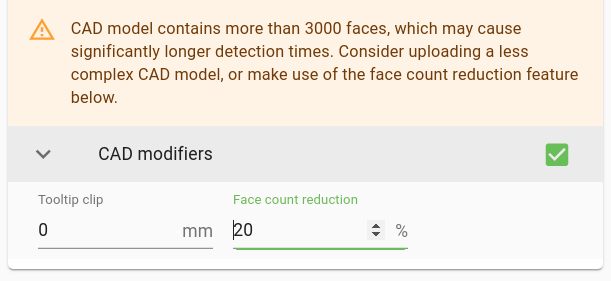

Use the face count reduction built into the CAD-based tool model.