Warning

You are reading the documentation for an older Pickit release (3.2). Documentation for the latest release (4.0) can be found here.

Software release 3.2

On the hardware side, Pickit 3.2 brings the M-HD2 to its camera lineup: A latest-generation high-definition camera that brings high accuracy with an ultra-compact form factor and a robust Ethernet connection.

On the software side, we’re introducing DeepAL, a detection engine for the depalletization of semi-structured parts like boxes, totes and buckets. We also support teaching 3D box models, and introduce a number of improvements for getting more pickable parts from a Pickit detection.

Read on to learn more!

Camera hardware

New M-HD2 camera

The M-HD2 is a high-definition camera that combines the following outstanding features:

Two times better camera accuracy and a wider view angle than the Pickit M-HD camera.

Compact form factor and lightweight, making it ideal for robot-mounted operation on industrial robots and cobots alike.

Ethernet communication with the Pickit processor.

Find out more, including its technical specifications, in our cameras overview.

Software improvements

New DeepAL detection engine

Pickit DeepAL is a detection engine specially designed for unmixed depalletization applications, where the parts to pick are mostly flat and stacked in layers in semi-structured patterns. Typical applications include the depalletization of boxes, totes and buckets.

DeepAL combines both depth and color information into a state-of-the art deep learning algorithm, which enables it to:

Teach parts fast. No training required, just show it to the camera and you’re ready to go!

Detect the correct orientation of a box based on its color pattern. DeepAL is quite tolerant to changing lighting conditions.

Detect plain boxes with no color pattern.

Detect parts in any pattern. Pickit doesn’t need to know about how the parts are laid out, and the pattern can change from one layer of the pallet to the next.

Detect parts that have moved (and even tilted), as can happen on pallet top layers.

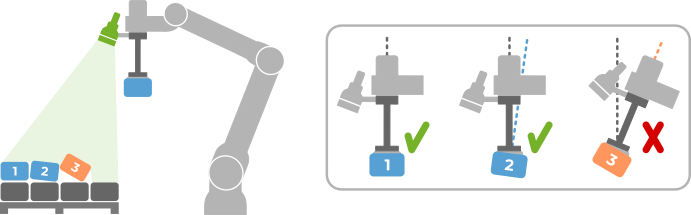

Better support for 4-axis robots

Robots with four axes are quite common in depalletizing applications, and are already supported by Pickit. As opposed to robots with six (or more) axes, their end-effector cannot tilt with respect to the vertical. In Pickit 3.2, it’s easy to enforce this contraint, yet take into account the fact that robot tools often tolerate some tilt without compromising pick success.

In the example below, parts 1 and 2 can be picked with a 4-axis robot (using tool tilt for part 2). Part 3 is too tilted for a 4-axis robot with this tool, and is labeled as unpickable.

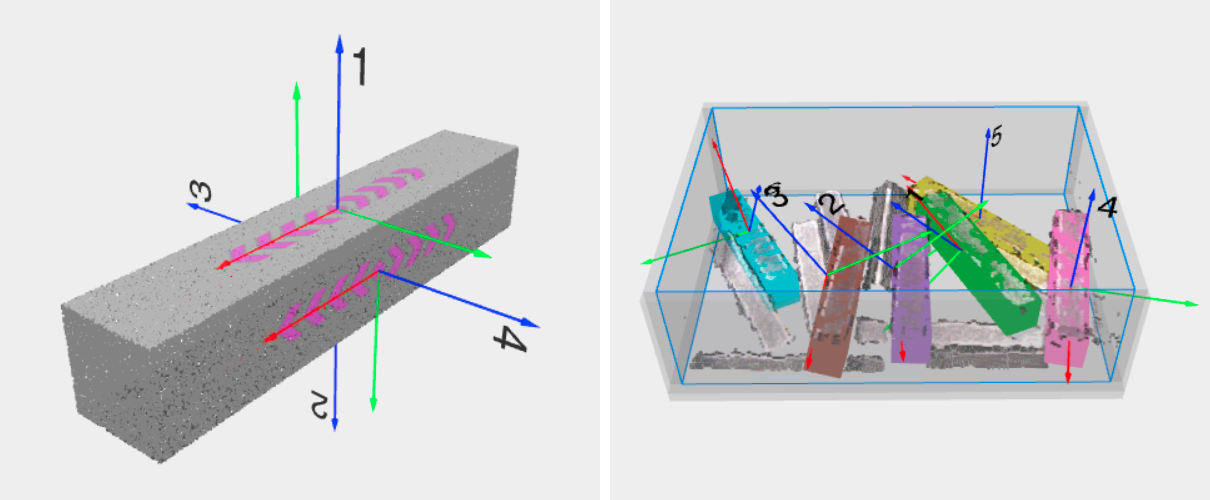

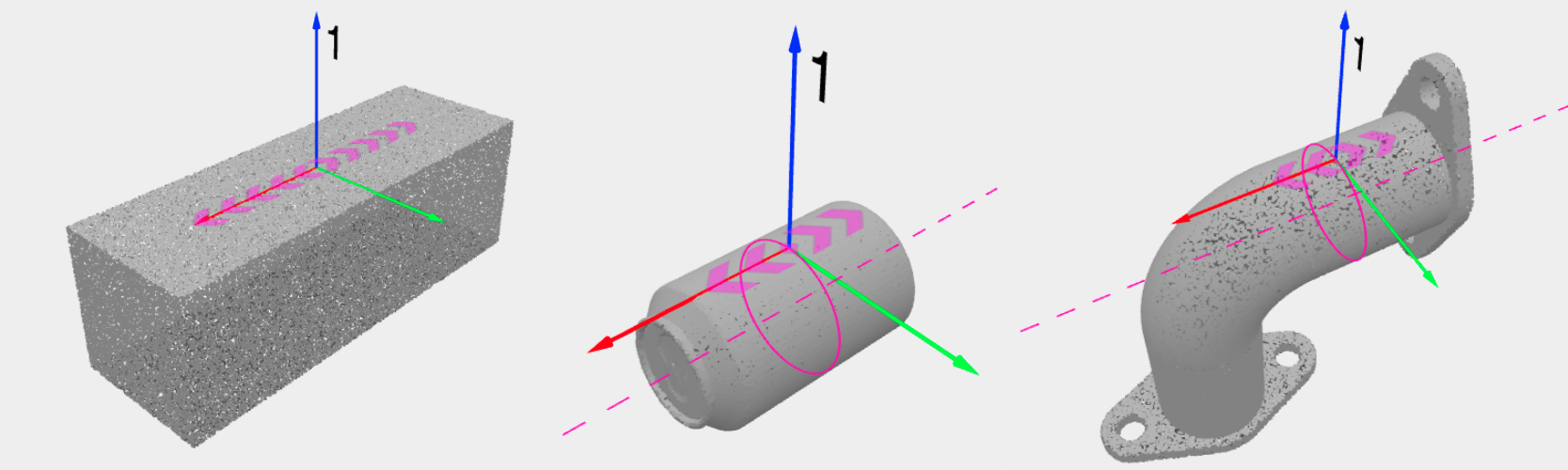

Teach box model

The Teach engine has been upgraded to support 3D box models. This model type is recommended for applications with randomly oriented box-shaped objects of known dimensions, such as billets with a square cross-section. Whereas before you had to teach a box part by placing it under the camera or uploading a CAD file, now you only need to specify its dimensions, similarly to how it’s done for cylinders.

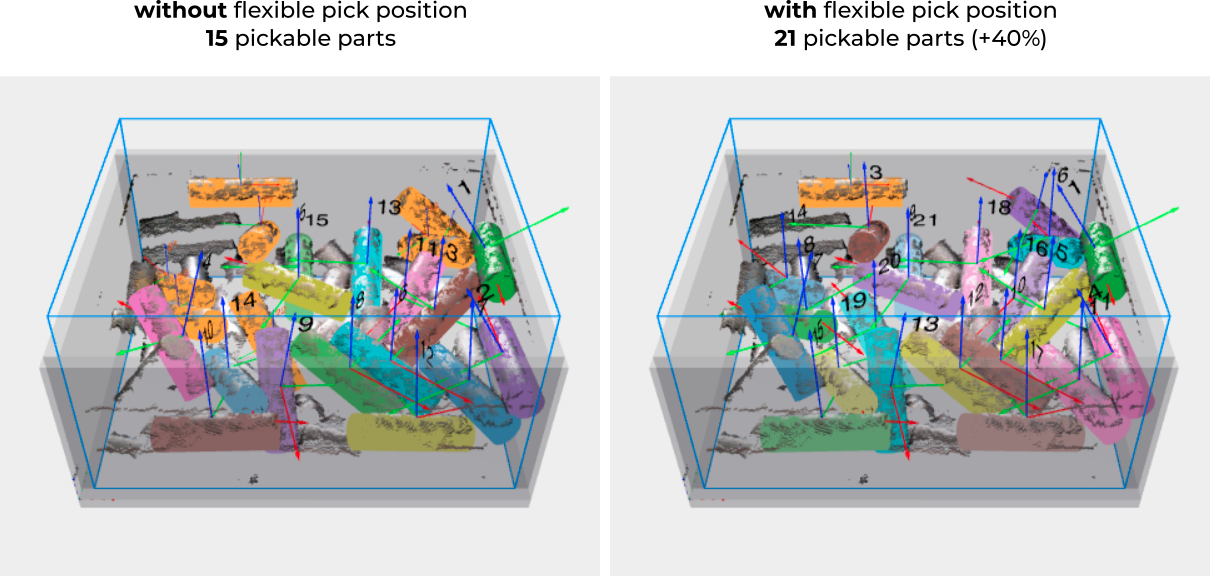

Flexible pick position

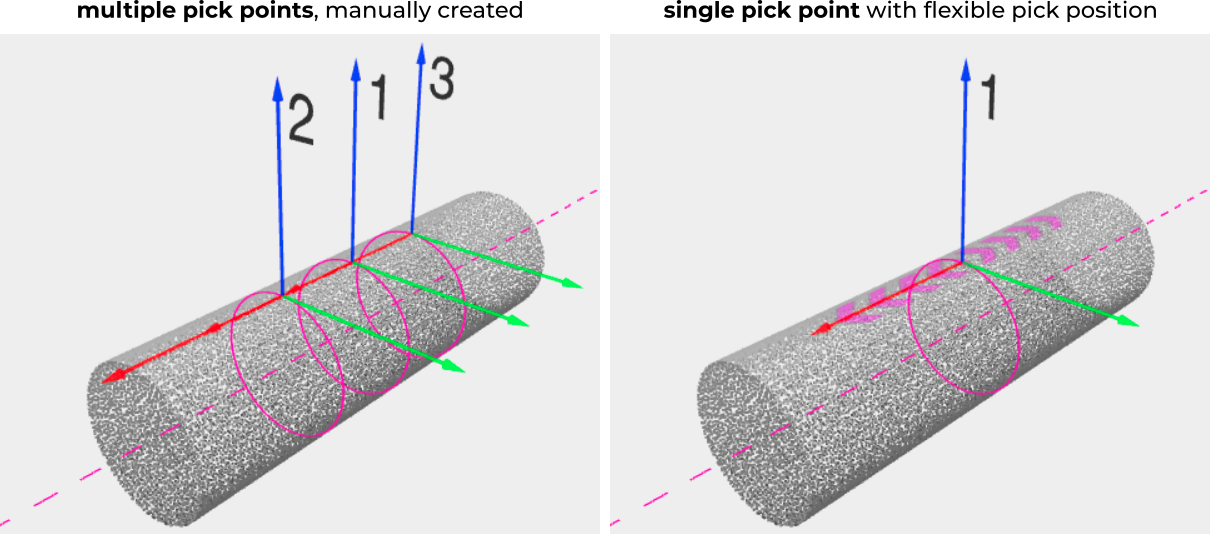

Some picks tolerate translations along a direction without compromising pick success. Pickit allows specifying this flexible pick position and will exploit it when selecting how to pick a part. In the example below, enabling this feature increases pickable parts by 40%.

Instead of having to manually create and manage multiple pick points (below left), you can now conveniently specify a region around a single pick (below right, magenta arrows).

Flexible pick position can be added to any pick point of a Pickit Teach model.

More part pickability insights

When monitoring your picking application, you might sometimes wonder:

Why is this part unpickable?

Why is this part picked like that?

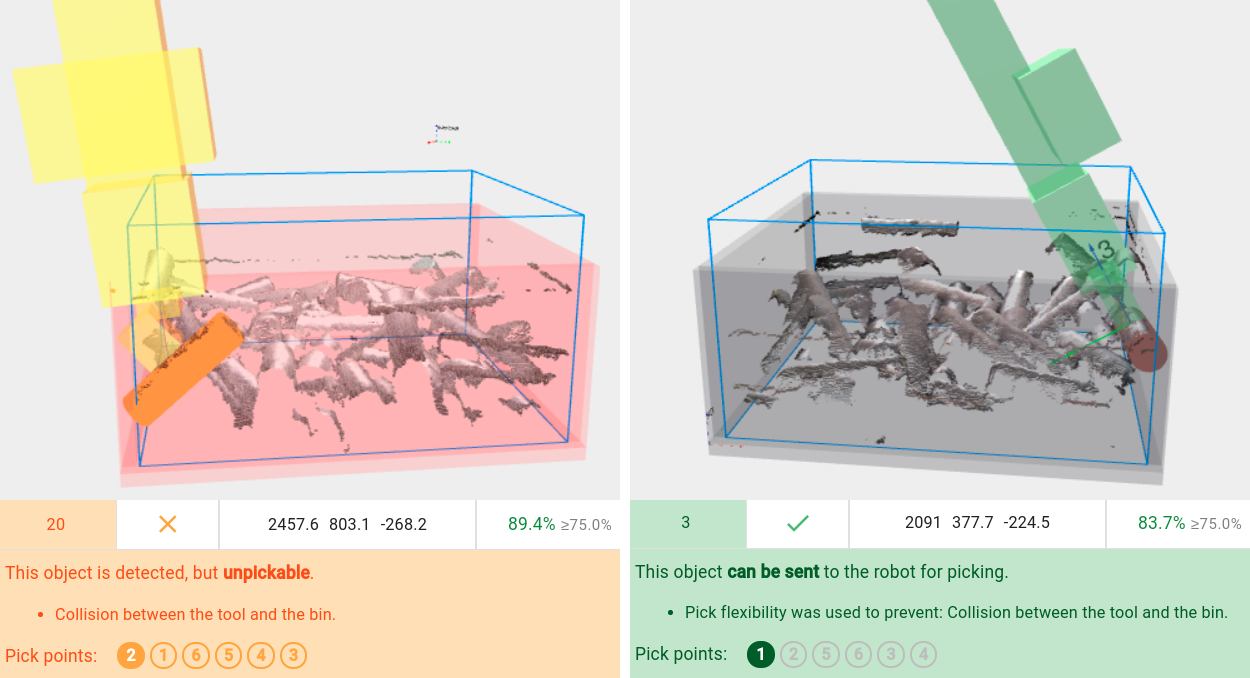

Pickit already provided good feedback to answer the first question, and version 3.2 extends the feedback reported for pickable parts to answer the second question. Pickit leverages multiple sources of pick flexibility to find valid picks, and you can learn the reason why it was used by inspecting the viewer and objects table. In the examples below, we see:

Left: The part is unpickable part due to a collision with the bin. There is not enough pick flexibility to produce a valid pick.

Right: The part is pickable, but the preferred pick (vertical tool) collides with the bin. Pick flexibility is used to prevent this collision.

Tool and pick point goodies

We didn’t want to close these notes without pointing out a few improvements that we’re rolling out to make your application setup a little easier:

The Pickit billet picker has grown into a family of six different variants. Selecting any of them as a tool to use for picking is a single click away!

Clipping the bottom of a robot tool template is now a single click operation. A typical usecase is removing the tip of a flexible suction below so it’s not part of the collision prevention checks.

You can renumber pick points to your liking, and group similar pick points together. For example, pick points on the top of a part are 1-5, while pick points on the bottom are 10-15.

You can copy settings of one pick point (eg. tool, location, symmetry axis) to others, preventing tedious manual work.

Get the update now

If you have an older Pickit version and would like to try 3.2, check out how you can upgrade your system.