Warning

You are reading the documentation for an older Pickit release (3.2). Documentation for the latest release (4.0) can be found here.

How to improve picking accuracy?

Accuracy, trueness and repeatability

Before diving into the picking accuracy details, it is important to clarify the main concepts that will be used throughout this article. Our terminology is inspired by the ISO 5725 standard.

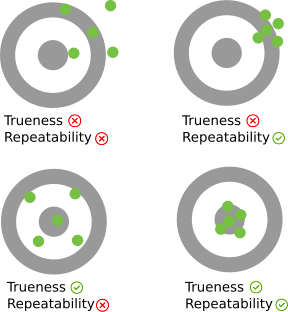

Trueness measures how close to reality a measurement is, on average. It is related to the statistical concept of bias.

Repeatability measures how close measurements taken in the same conditions are from each other. It is also called precision and is related to the statistical concept of variance.

Accuracy measures how close to reality a measurement can be. It is a combination of both the trueness and the repeatability.

Trueness and repeatability are therefore two independent concepts. As shown in the image below, a measurement with a good trueness can have a bad repeatability and vice versa. Good accuracy can only be obtained with both good trueness and good repeatability.

Picking accuracy overview

The picking accuracy of an application depends on many components. To improve it, it is important to first identify the main sources of inaccuracy.

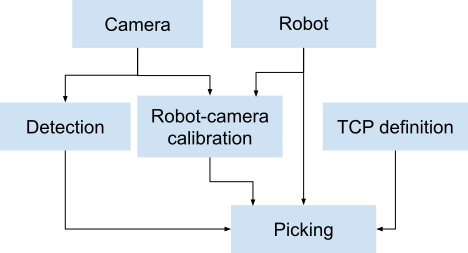

The diagram below introduces all the components affecting picking accuracy. The total picking error results from the combination of all these sources.

Tip

As shown in the diagram, some sources of inaccuracy are independent (like the robot accuracy) while other are coupled. For example, the robot-camera calibration accuracy is affected by both the camera and the robot accuracy. When investigating the picking accuracy of an application, it is recommended to first check the independent sources of error before checking the coupled ones.

Below, you can find for each component a procedure to verify its accuracy and, if needed, to correct it: