Warning

You are reading the documentation for an older Pickit release (3.1). Documentation for the latest release (4.0) can be found here.

Software release 3.1

Pickit 3.1 is a release focused on the stability and robustness of your application. Our camera hardware has been hardened to operate in challenging environments like forges and foundries, where strong sources of electromagnetic interference and vibration are typical, and cameras are often mounted on large industrial robots.

A good robot-camera calibration is key for having accurate picks, and on the software side we have greatly improved the user experience for making this a minimal-friction task. And because we love amazing user experiences, we are also introducing a number of improvements that make your life easier both when setting up your application, as well as when it’s running in production!

Camera hardware

The Pickit non-HD cameras count with a new set of cables specially designed for challenging environments, especially when mounted on the robot, such that:

It is long enough to be mounted on large industrial robots.

The segment that can be routed through the robot can resist the bending and torsion typical of robot motions.

It is compliant with the Electrical Fast Transient (EFT) - IEC/EN61000-4-4 immunity standard.

Calibration

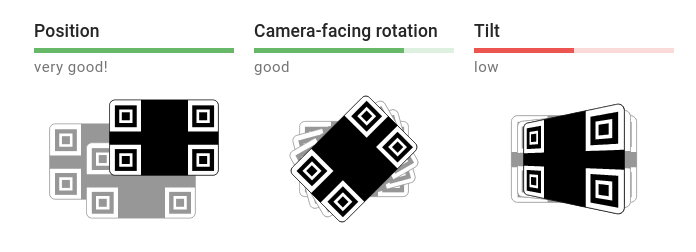

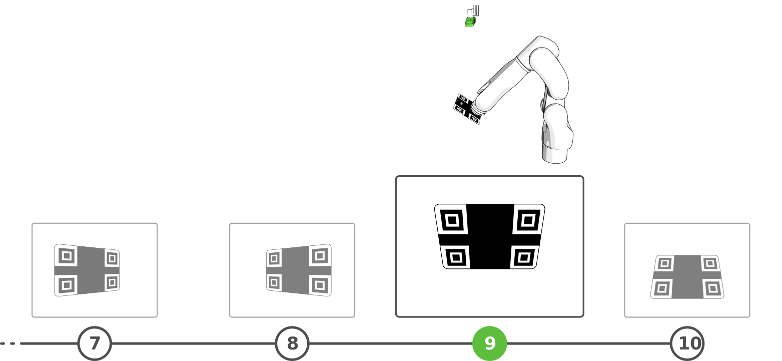

We heard your feedback that performing robot-camera calibration can sometimes be challenging, in particular the process of pose collection. Since it is very important that poses are distinct enough to produce an accurate calibration (and contribute to accurate picks), in Pickit 3.1 we’re introducing a new pose collection experience with the following highlights:

Next recommended pose We guide you through the process of pose collection by showing which pose to capture next, as it would be seen from your (external) point of view, as well as from the camera. The set of recommended poses has also incremented from five to ten, to further improve accuracy.

Software improvements

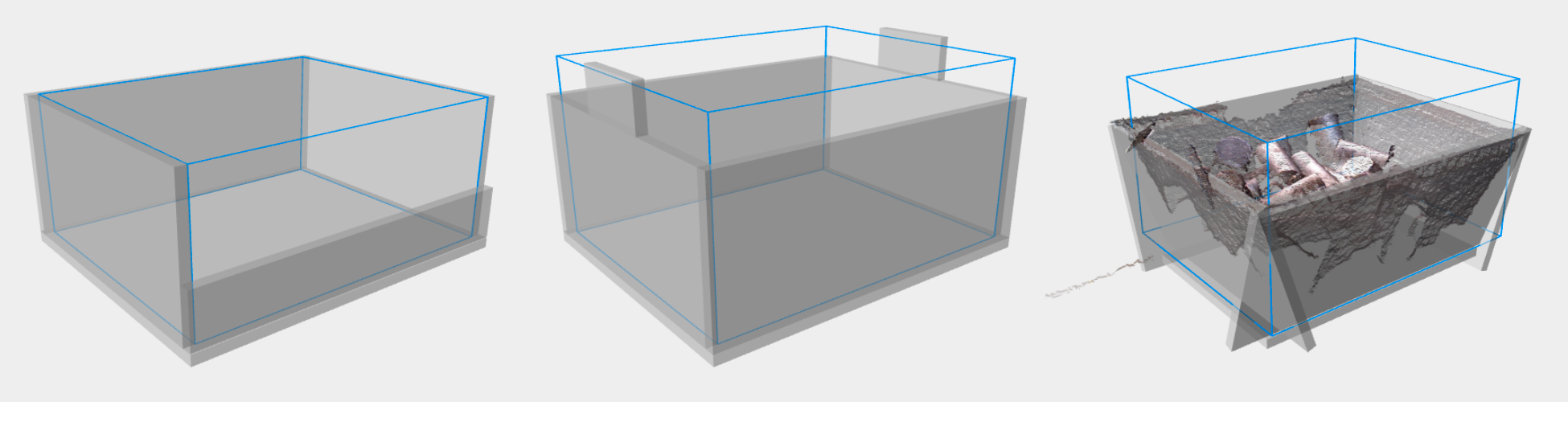

Collision environment

Pickit allows performing collision prevention for the robot tool model at the pick point. Collisions can be with the 3D scene visible to the camera, or with user-defined obstacles.

Up to Pickit 3.0, the only possible user-defined obstacle was a box-shaped bin. In Pickit 3.1, the new collision environment allows you to define more complex bins, as well as obstacles outside the bin like fences. Examples of bins that go beyond a simple box are bins with open sides, bins with handles, and bins with slanted walls.

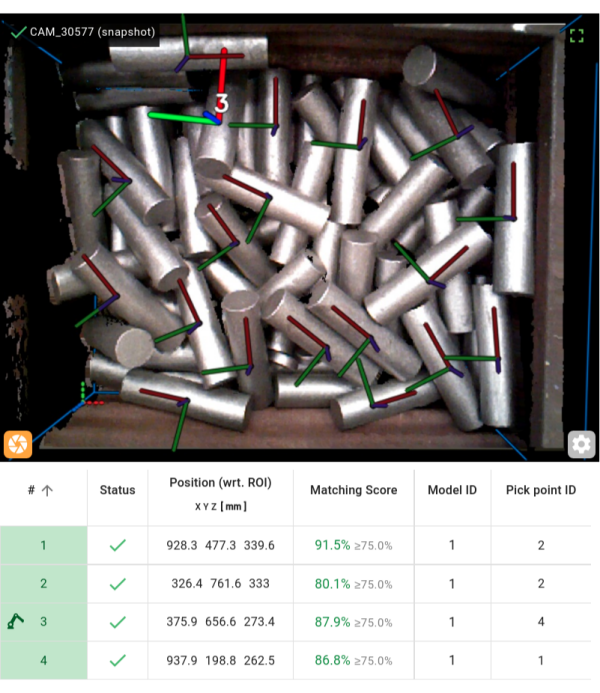

Last object sent to the robot

In bin picking, when a pick doesn’t succeed and multiple objects were found, it’s a common practice to attempt picking the next object in the list without running a new detection. In other applications, like depalletizing, it’s usual to pick multiple (or all) objects from the same detection.

In Pickit 3.1, you can visually keep track of which object was last sent to the robot. It is highlighted in the viewer, and a robot icon is shown next to it in the objects table.

Less visual clutter in the web interface

Pickit provides good defaults for many application settings. For the ones that need to be modified or optimized beyond the defaults for your application, the web interface should make it easy for you to find and understand them.

To this end, the Pickit 3.1 web interface reduces visual clutter in a few key places, so you can easily learn what’s possible in Pickit, and find the setting you’re looking for. Below, you see a comparison between the pick point editors of Pickit 3.0 and 3.1. In the right image, it’s clearer that pick points have four main setting categories.

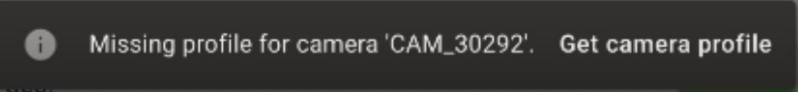

Automatic camera profile download

Non-HD cameras require a camera profile to produce high-quality 3D images. Pickit systems ship with the profile of the camera they originally came with. However, if you replace the camera or add an additional one, you need to get the profile of this new camera.

The process for getting a new camera profile is now straightforward, and consists of a single click if the computer from which you open the web interface (not the Pickit processor) has Internet access.

Upgrading from version 3.0

At Pickit, we strive to provide a transition between Pickit versions that is as smooth as possible. However, sometimes a manual user action is required. The following list outlines the few situations where this is the case. If any of them applies to your application, make sure to take them into account:

If you perform calibration automatically from a robot program, it probably uses five calibration poses and might fail because they don’t score high enough. When this is the case, test these poses in the web interface calibration wizard to confirm their quality. We recommend extending the robot program to use the new set of ten recommended poses.

Warning

The ten first M-HD cameras shipped prior Jan. 2019 are no longer supported in Pickit 3.1. These cameras won’t operate with Pickit after an upgrade. Owners of these cameras have been contacted directly by the Pickit after-sales support team.

Get the update now

If you have an older Pickit version and would like to try 3.1, check out how you can upgrade your system.