Warning

You are reading the documentation for an older Pickit release (3.2). Documentation for the latest release (4.0) can be found here.

Example calibration program

Loading the program

This example program requires the Pickit TMflow components to be installed in your robot. For installation instructions of both the TMflow components and the example programs, please refer to the Component installation and setup article.

Click the hamburger icon on the top-left corner of the user interface, and select Project.

Open the project called pickit_calibration. This program is a template for performing multi-poses calibration.

Multi poses calibration

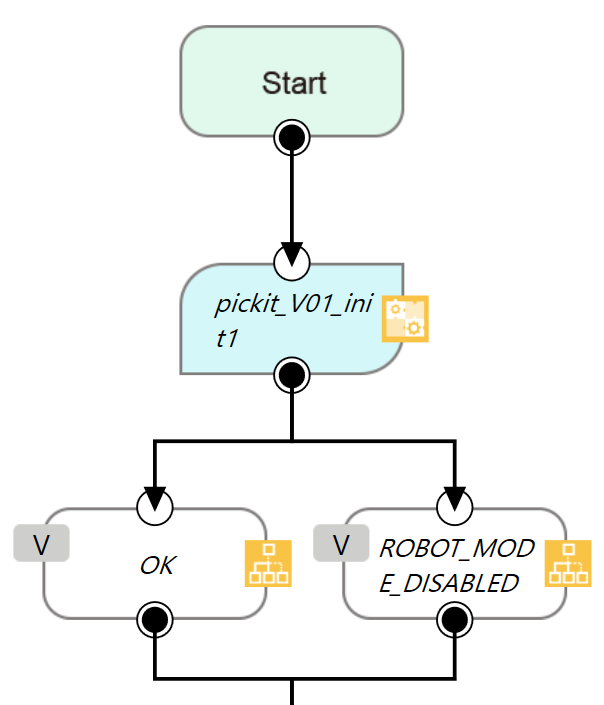

The program starts by initializing pickit with the init component. Note that since robot mode doesn’t need to be enabled to perform calibration, both exit states of the component map to the nominal program flow.

Note

If your Pickit system is not using the default 169.254.5.180 IP address, you should set it in the configuration of the init component.

Then, the following sequence is repreated five times:

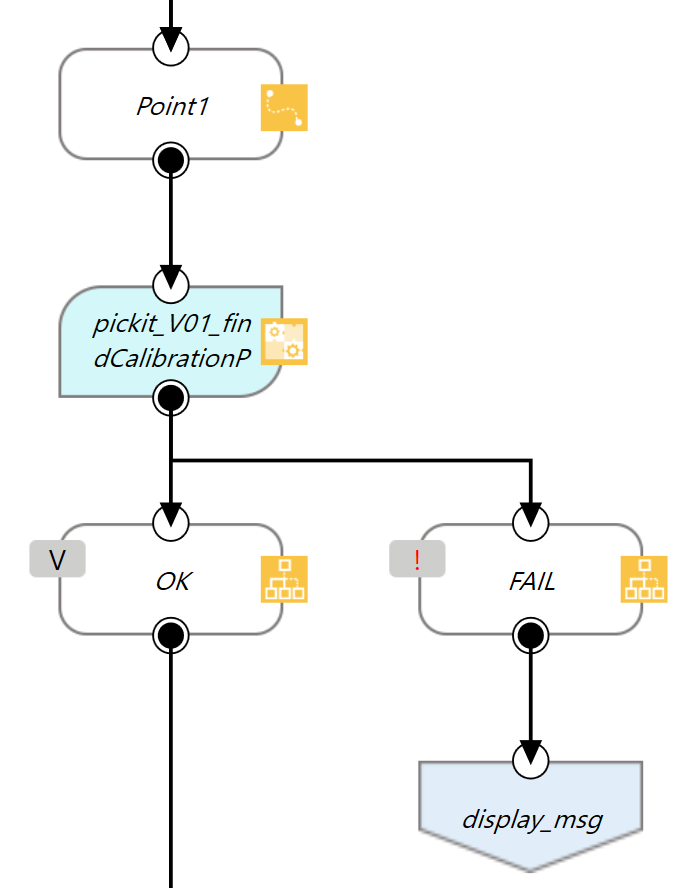

Move the robot to a point where the calibration plate is visible.

When teaching the points, it is recommended to have the Calibration page open in the Pickit web interface, where the user can verify whether the calibration plate is visible.

Note

This program is a template, and the points need to be retaught by the user since they depend on the physical environment and location of the calibration plate. Refer to the multi-poses calibration article for guidelines on how the five points should be taught.

Send a request to find the calibration plate by means of the findCalibrationPlate component.

It is possible to follow the progress of the calibration procedure from the Calibration page.

Single pose calibration

For single pose calibration, the program is similar, but only performs a single calibration request.

Running the program

Before running the calibration program, you can optionally activate the Calibration page in the Pickit web interface, which provides feedback on calibration plate visibility and progress of the calibration process (more).