Warning

You are reading the documentation for an older Pickit release (3.4). Documentation for the latest release (4.0) can be found here.

How to route the cables of a robot-mounted camera?

A robot-mounted camera can bring many benefits to your application, but requires the camera cables to be correctly routed from the robot base to the camera. This article covers a number of best practices that should be taken into account to ensure reliable operation and prevent common installation mistakes.

Use only officially supported cables (learn more), which comply with the electrical and mechanical characteristics required by robotic picking applications.

Use a cable dress pack adapted to your robot setup. It ensures the minimum bending radius of your cables is respected, and can also have torsion stops. It also prevents excessive cable wear, as well as jamming or tangling of cables with workcell elements. Consult the specifications of your camera cables to learn more about their mechanical characteristics.

Leave enough slack when the cable is routed around robot joints. The cable should comfortably accomodate to the range of motions the robot is expected to perform. This concern is sometimes addressed by the cable dress pack, and might contain a spring-loaded mechanism to handle cable slack.

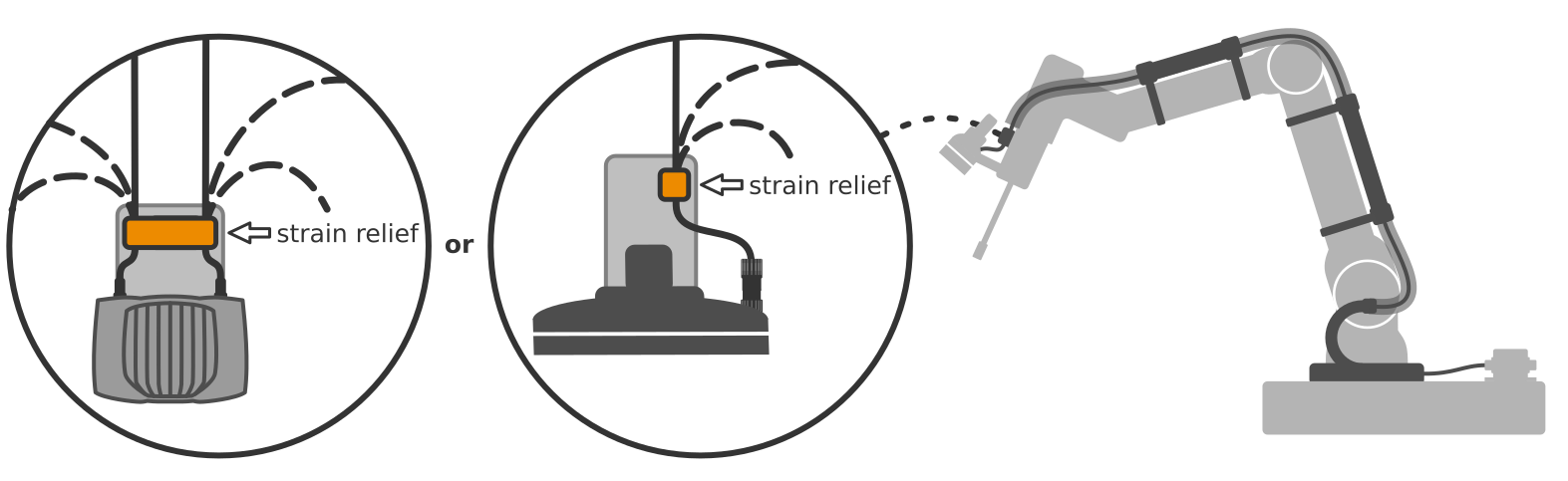

Place a strain relief in a location that moves rigidly with the camera. It prevents cable stress from reaching the camera.

Avoid routing any component of the camera cable too close to electromagnetic interference sources like robot actuators or power cables, especially when working with large robots.