Warning

You are reading the documentation for an older Pickit release (2.4). Documentation for the latest release (4.0) can be found here.

Complete pick and place program

Overview

This article presents a robot-independent pick and place logic that serves as a great starting point to build real applications on. It consists of a more feature-rich version of the simple pick and place logic, which presents the basic ideas behind pick and place. It is highly recommended to read that article first. A complete description of the Pickit interface can be found here.

All the logic presented here is written in robot-independent pseudo-code using a syntax similar to that of Python. The program can be downloaded here and, similar to the simple pick and place program, it consists of two main parts:

Generic pick and place function, which typically remains constant across applications.

Application-specific hooks that depend on things like the robot, the gripper, the part to pick and the cell layout.

Note

The code samples presented in this article are pseudo-code, and are not meant to be executed.

The minimum inputs required to run a pick and place program are the same as for the simple pick and place logic.

Generic pick and place function

1def pick_and_place(setup, product, target_picks=-1, retries=5):

2 if not pickit_is_running():

3 print("Pickit is not in robot mode. Please enable it in the web interface.")

4 halt()

5

6 before_start()

7 pickit_configure(setup, product)

8

9 goto_detection()

10 pickit_find_objects_with_retries(retries)

11 pickit_get_result()

12

13 picks = 0

14 while True:

15 if not pickit_object_found():

16 # There are no pickable objects, bail out.

17 break

18

19 # Compute pre-pick and post-pick points.

20 PrePick = compute_pre_pick(PickitPick)

21 PostPick = compute_post_pick(PickitPick)

22

23 if pickit_is_reachable(PickitPick, PrePick, PostPick):

24 # Object is pickable! Attempt pick.

25 pick_success = pick()

26 if pick_success:

27 picks += 1

28 done_picking = target_picks > 0 and picks == target_picks

29 if done_picking:

30 # Target picks reached. Place without further detections.

31 place()

32 break

33 else:

34 # Target picks not reached. Place and detect next object.

35 goto_detection()

36 pickit_find_objects_with_retries(retries)

37 place() # In parallel to detection, saves cycle time.

38 pickit_get_result()

39 else:

40 # Picking failed, skip place and detect next object.

41 on_pick_failure()

42 goto_detection()

43 pickit_find_objects_with_retries(retries)

44 pickit_get_result()

45 else:

46 # Object is unreachable, get the next detection, if any.

47 pickit_next_object()

48 pickit_get_result()

49

50 after_end()

51

52 return picks

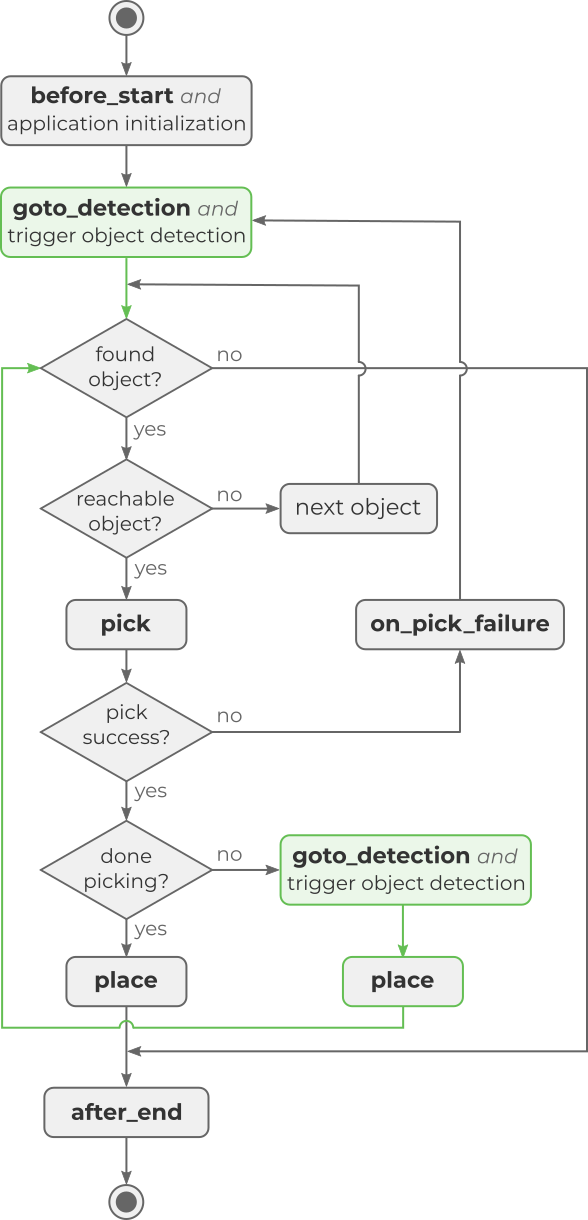

Click below to expand a flowchart of the implemented logic.

The lines that differ with respect to the simple pick and place logic are highlighted above, and implement the following additional features:

The ability to not only pick all objects (the default), but also to specify a target number of picks.

Some robot tools have the means to measure pick success. When this is available, cycle time can be optimized by skipping the place motion on pick failure, and instead proceed to trigger a new object detection.

Wrap the logic in a

pick_and_placefunction, so it can be reused more easily and with less code duplication. It outputs the number of successful picks, and takes as inputs:Required: the Pickit configuration,

setupandproduct.Optional:

target_picks, which defaults to -1 (pick all); andretries, which denotes how many times to retry object detection when the Region of Interest (ROI) is not empty, but no objects are detected.

Application-specific hooks

The pick_and_place function requires the following application-specific hooks to be defined.

Click on the entries below to expand them and learn more about their default implementation and behavior:

before_start

def before_start():

gripper_release()

This hook is executed once before starting to pick and place. It’s recommended to add logic required to bring the robot to a sane configuration before starting to pick objects. This can be especially useful when the robot program was previously interrupted at mid-run.

By default, it makes sure the gripper is open to prepare it for picking an object.

goto_detection

def goto_detection():

movej(Detect)

This is a motion sequence that moves the robot to the point from which object detection is triggered. For simple applications, this typically corresponds to a single waypoint.

Some applications using a robot-mounted camera might require a non-constant Detect point. For instance, when a bin is wider than the camera field of view, multiple detection points are required to fully cover it.

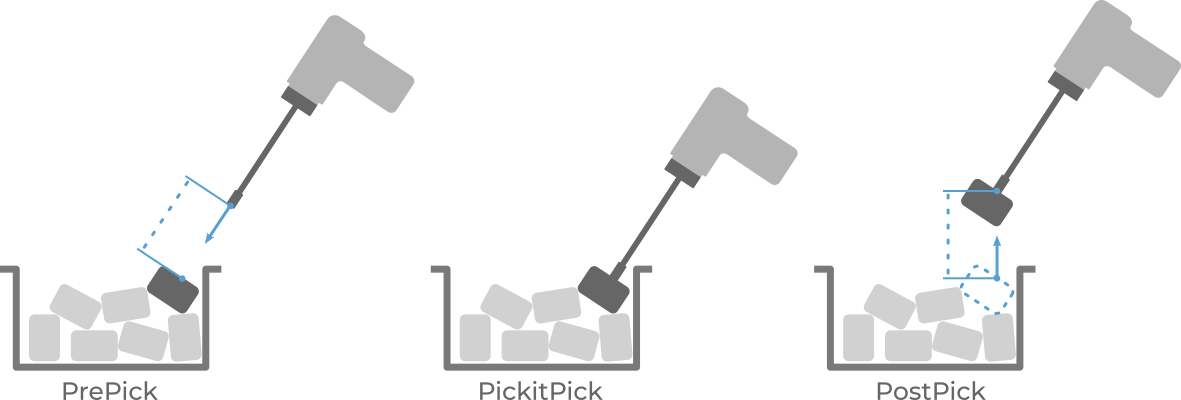

compute_pre_pick - compute_post_pick

def compute_pre_pick(PickitPick, pre_pick_offset=100):

PrePick = PickitPick * Pose(0, 0, -pre_pick_offset, 0, 0, 0)

return PrePick

def compute_post_pick(PickitPick, post_pick_offset=100):

PostPick = PickitPick

PostPick.z = PostPick.z + post_pick_offset

return PostPick

These hooks compute PrePick and PostPick from the pick point.

They are used in the linear approach and retreat motions of the pick sequence.

PrePickis chosen such that the approach motion is aligned with the object.PostPickis chosen for a straight-up retreat (which makes it less likely to collide with obstacles like the bin).

The above strategies have proven to be effective in practice, but they can be overridden by different ones, if desired.

pick

def pick():

movej(AbovePickArea)

movel(PrePick)

movel(PickitPick)

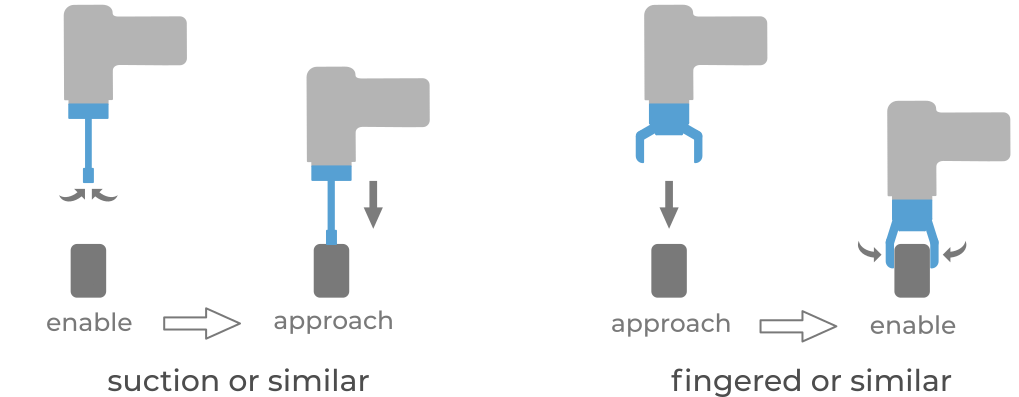

gripper_grasp() # For a suction-like gripper, do this one line above.

movel(PostPick)

movel(AbovePickArea)

return gripper_pick_success()

Note

movej(p) and movel(p) represent a robot motion to reach waypoint p following a path interpolated linearly in joint or Cartesian space, respectively.

The pick sequence performs the actual picking motion, which consists of a linear approach to the pick point, a grasping action, and a linear retreat away from it.

The sequence starts and ends at

AbovePickArea, a waypoint known to be reachable without collision both from the pick area and from the other user-defined waypoints.The place where

gripper_grasp()is called depends on the type of gripper. Fingered grippers perform the grasp action at the pick point, but for suction-like grippers this typically takes place before heading to the pick point.The pick point,

PickitPick, is computed by Pickit.The

PrePickandPostPickpoints are computed in their respective hooks.It returns a boolean indicating whether the pick was successful.

Note

The check represented by

gripper_pick_success()assumes that the gripper has the means to check pick success from sensor input (like vacuum or force). If this is not the case for your gripper, thepick()function can simplyreturn Truealways, and the pick failure logic will never be triggered.

on_pick_failure

def on_pick_failure():

gripper_release()

This hook is executed whenever the pick success check fails, (see gripper_check_success() in the pick hook).

The default implementation opens the gripper to prepare it for picking the next object.

place

def place():

movej(Dropoff)

gripper_release()

This sequence places the object at the specified dropof location. For simple applications the implementation is trivial, as shown above. However, some applications require more advanced place motions.

The robot sometimes needs to know about the way the object was picked, in order to place it appropriately. Refer to the smart placing examples to learn how to do this with minimal programming effort.

It can also be the case that the drop-off point is not constant, as when parts need to be stacked or palletized.

Many robot programming languages provide helpers and templates for stacking and palletizing, which can replace the fixed Dropoff point.

after_end

def after_end():

if not pickit_object_found():

if pickit_empty_roi():

print("The ROI is empty.")

elif pickit_no_image_captured():

print("Failed to capture a camera image.")

else:

print("The ROI is not empty, but the requested object was not found or is unreachable.")

This hook is executed once after pick and place has finished. The proposed implementation identifies the termination reason and prints an informative statement if there are no more pickable objects. This is very useful to debug your application while you’re setting it up.

When getting your application ready for production, you should handle the cases that make sense to you with appropriate logic. For instance, a continuous-running application might want to request more parts once all pickable objects have been processed.

def after_end():

# Unrecoverable error. Raise alarm and stop program.

if pickit_no_image_captured():

alarm("Failed to capture a camera image.")

halt()

if not pickit_empty_roi():

# Save a snapshot to learn why no objects were detected in a non-empty ROI.

pickit_save_snapshot()

# Request more parts to start picking all over again.

feed_more_parts()

Notice how the application only stops on non-recoverable errors, and triggers saving a snapshot whenever it fails to empty the ROI. Inspecting these snapshots allow to improve the application by answering questions like:

Are there actually unpicked objects in the ROI, or are there unexpected contents in it?

If there are objects, are they detected but unpickable by the robot (because they are unreachable or the picking action failed)?

If there are objects, but they are not detected, can we optimize the detection parameters or camera location to make them detectable?

Example usage

The following is a minimal example of how the pick and place function can be used.

# Application inputs (needs replacing with actual values).

Detect = [x,y,z,rx,ry,rz]

AbovePickArea = [x,y,z,rx,ry,rz]

Dropoff = [x,y,z,rx,ry,rz]

setup = 1

product = 1

def gripper_release():

# Add custom gripper release logic.

def gripper_grasp():

# Add custom gripper grasp logic.

def gripper_pick_success():

# Add custom gripper pick success check. Returns a boolean.

# If you don't have the means to measure pick success, return always True.

# Pick all objects and write number of successful picks to 'picks'.

picks = pick_and_place(setup, product)

Advanced topics

Robot-mounted camera

If a robot-mounted camera is used, it’s not possible to perform multiple detection retries (including camera captures) in parallel to the place motion sequence, as camera capture can only take place from the Detect point.

To correctly handle the robot-mounted camera scenario, replace lines 31-34 with the following:

# Try first a single detection in parallel to place...

goto_detection()

capture_ok = pickit_capture_image()

if capture_ok:

pickit_process_image()

place()

pickit_get_result()

# If not successful, detect with retries. No longer in parallel with motions.

if not capture_ok or not pickit_object_found():

goto_detection()

pickit_find_objects_with_retries(retries)

pickit_get_result()

Notice the use of the functions pickit_capture_image() and pickit_process_image().

A variant of the pick and place function with the above changes, named pick_and_place_robot_mounted, can be downloaded here.