Warning

You are reading the documentation for an older Pickit release (3.4). Documentation for the latest release (4.0) can be found here.

KUKA bin picking program

This program requires that Pickit is installed and set up with your robot. For installation instructions, please refer to the KUKA installation and setup article.

Attention

The examples contained in the Pickit application files contain hard-coded robot poses that should be adapted to every new robot. When executing such programs for the first time, please do so in manual mode and at low speed to check for potential collisions.

The PickitBinPicking program

This program can be found in R1 > Program > Pickit.

Note

This program only works with Pickit software version of 2.2 or greater. If you are using a software version prior 2.2, please contact us at support@pickit3d.com, and we will assist you in finding a solution.

DEF PickitBinPicking( )

;FOLD Collision detection settings

;---------------------------------

;Collision recovery for KSS 8.5 and 8.6

;Set the correct LOAD DATA

;Declare the collision detection interrupt to stop the search motion

INTERRUPT DECL 25 WHEN $CYCFLAG[255] == TRUE DO RetreatWhenFound()

$CYCFLAG[255]=FALSE

;Define a cycle flag on the peak values for all axes

$CYCFLAG[255]=(($COLLMON_MAX[1]>iSearchSensitivity[1]) OR($COLLMON_MAX[2]>iSearchSensitivity[2])OR($COLLMON_MAX[3]>iSearchSensitivity[3])OR($COLLMON_MAX[4]>iSearchSensitivity[4])OR($COLLMON_MAX[5]>iSearchSensitivity[5])OR($COLLMON_MAX[6]>iSearchSensitivity[6]))

;Start collision monitoring in the system

;The data set ColDetect[1] is here used as the active data set

;for global collision detection

;Use ColDetect[1] for all motions of the robot except those in the pick()

;routine where the collision recovery is used

;ColDetect[1] can be edited in Configuration->Collision Detection

USE_CD_PARAMS(1)

;ENDFOLD

PTP XHOME

IF NOT Pickit_is_running() THEN

PickitMessages(#info, 1)

HALT

ENDIF

;Fill in correct setup and product id

Pickit_configure(1,1)

;Set the tool used for picking, make sure the TCP is defined correctly

BAS(#TOOL,1)

BAS(#BASE,0)

PTP XDetect

WAIT SEC 0.0 ;Wait until the robot reaches the position

Pickit_detect_with_retr(5)

WAIT FOR Pickit_get_results()

LOOP ; ---- Main Loop

IF Pickit_object_found() THEN

;Five-points extraction path

F_Pick=Pickit_get_pose()

;F_RelFrame is used to apply the prepick and postpick offsets

F_RelFrame={X 0,Y 0,Z 0,A 0,B 0,C 0}

F_RelFrame.Z=PrePickOffset

F_PrePick=F_RelFrame:F_Pick

F_RelFrame.Z=PostPickOffset

F_PostPick=F_RelFrame:F_Pick

F_BinEntry=F_PrePick

F_BinExit=F_PostPick

F_BinEntry.Z=BinEntryZ

F_BinExit.Z=BinExitZ

;Check if positions are reachable

IF IsReachable() THEN

PTP XAbovePickitArea

;FOLD set collision recovery parameters for the picking sequence

;Activate the collisions detection interrupt

INTERRUPT ON 25

;Reset the peak values

RESET_CM_MAX()

;Make sure the cycle flag is low before starting the motion

WAIT FOR NOT $CYCFLAG[255]

;ENDFOLD

;Picking sequence

;This is the search routine where collision recovery will be applied

Pick()

;FOLD reset collision recovery parameters after picking is done

;Go back to the global collision detection settings

;If a collision happens now, the robot will stop

USE_CD_PARAMS(1)

;Deactivate the collisions detection interrupt

INTERRUPT OFF 25

;Make sure the advance run is not leaving the pick() subroutine

;before the interrupt is deactivated

WAIT SEC 0

;ENDFOLD

PTP XAbovePickitArea

PTP XDetect

WAIT SEC 0.0

Pickit_capture_image()

Pickit_process_image()

;Drop the picked part at the needed locationS

PTP XDrop

;------- Add release logic

WAIT FOR Pickit_get_results()

IF NOT Pickit_object_found() THEN

;Retry detecting if no object found during the first detection.

PTP XDetect

WAIT SEC 0.0

Pickit_detect_with_retr(4)

WAIT FOR Pickit_get_results()

ENDIF

ELSE ;Position unreachable, try picking the next object

PickitMessages(#info,2)

Pickit_next_object()

WAIT FOR Pickit_get_results()

ENDIF

ELSE ;No Object found, exit

IF Pickit_roi_empty() THEN

PickitMessages(#info, 3)

EXIT

ELSE

PickitMessages(#info, 4)

Pickit_save_scene()

EXIT

ENDIF

ENDIF

ENDLOOP

END

The structure of this program is similar to the simple pick and place program.

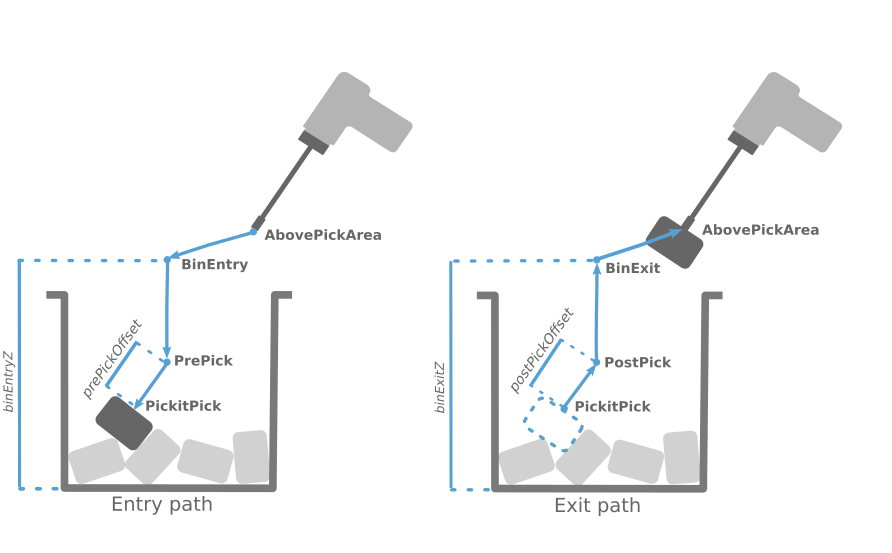

Program subroutines

In this program, the picking motion commands are executed in a separate subroutine. To pick a detected part, the robot needs to follow the five point extraction path recommended for picking in deep bins. More information about the five-point extraction path can be found in the robot-independent complete pick and place program.

DEF Pick()

;Conservative LIN motion parameters inside the bin

BAS(#VEL_CP,30)

BAS(#ACC_CP,20)

LIN F_BinEntry

LIN F_PrePick

LIN F_Pick

;----- Add grasping logic

WAIT SEC 1.0 ;Wait until grasping is completed

LIN F_PostPick

LIN F_BinExit

END

The IsReachable() subroutine is defined to perform a reachability check on the five points of the extraction path:

DEFFCT BOOL IsReachable()

Pickit_ErrStatCheckPos1=0

Pickit_ErrStatCheckPos2=0

Pickit_ErrStatCheckPos3=0

Pickit_ErrStatCheckPos4=0

Pickit_ErrStatCheckPos5=0

$TARGET_STATUS=#SOURCE

;Note: The INVERSE function cannot guarantee that a LIN motion will be feasible

PickitAxistest=INVERSE(F_Pick,xAbovePickitArea,Pickit_ErrStatCheckPos1)

PickitAxistest=INVERSE(F_PrePick,xAbovePickitArea,Pickit_ErrStatCheckPos2)

PickitAxistest=INVERSE(F_PostPick,xAbovePickitArea,Pickit_ErrStatCheckPos3)

PickitAxistest=INVERSE(F_BinEntry,xAbovePickitArea,Pickit_ErrStatCheckPos4)

PickitAxistest=INVERSE(F_BinExit,xAbovePickitArea,Pickit_ErrStatCheckPos5)

IF (Pickit_ErrStatCheckPos1 == 0) AND (Pickit_ErrStatCheckPos2 == 0) AND (Pickit_ErrStatCheckPos3 == 0) AND (Pickit_ErrStatCheckPos4 == 0) AND (Pickit_ErrStatCheckPos5 == 0) THEN

RETURN(TRUE)

ELSE

MsgNotify("Pose Unreachable by the Robot")

RETURN(FALSE)

ENDIF

ENDFCT

The RetreatWhenFound() subroutine is called when a collision is detected inside the Pick() subroutine.

It performs a recovery motion to F_PostPick before resuming the PickitBinPicking() routine.

DEF RetreatWhenFound()

;Deactivate the collision detection interrupt

INTERRUPT OFF 25

;Stop the active robot motion

BRAKE FF

;FOLD Message: Give peak value of collided axes

IF ($COLLMON_MAX[6]>iSearchSensitivity[6])THEN

MsgNotify( "Measured peak A6 = %1","Collision recov", $COLLMON_MAX[6])

MsgNotify( "Collision limit A6 = %1","Collision recov", iSearchSensitivity[6])

ENDIF

IF ($COLLMON_MAX[5]>iSearchSensitivity[5])THEN

MsgNotify( "Measured peak A5 = %1","Collision recov", $COLLMON_MAX[5])

MsgNotify( "Collision limit A5 = %1","Collision recov", iSearchSensitivity[5])

ENDIF

IF ($COLLMON_MAX[4]>iSearchSensitivity[4])THEN

MsgNotify( "Measured peak A4 = %1","Collision recov", $COLLMON_MAX[4])

MsgNotify( "Collision limit A4 = %1","Collision recov", iSearchSensitivity[4])

ENDIF

IF ($COLLMON_MAX[3]>iSearchSensitivity[3])THEN

MsgNotify( "Measured peak A3 = %1","Collision recov", $COLLMON_MAX[3])

MsgNotify( "Collision limit A3 = %1","Collision recov", iSearchSensitivity[3])

ENDIF

IF ($COLLMON_MAX[2]>iSearchSensitivity[2])THEN

MsgNotify( "Measured peak A2 = %1","Collision recov", $COLLMON_MAX[2])

MsgNotify( "Collision limit A2 = %1","Collision recov", iSearchSensitivity[2])

ENDIF

IF ($COLLMON_MAX[1]>iSearchSensitivity[1])THEN

MsgNotify( "Measured peak A1 = %1","Collision recov", $COLLMON_MAX[1])

MsgNotify( "Collision limit A1 = %1","Collision recov", iSearchSensitivity[1])

ENDIF

WAIT SEC 2

;ENDFOLD

;-------- Add release logic in case a part was picked

;To recover from the collision, skip to the last pose in the picking sequence

;This is important because the tool could still be inside the bin

LIN F_PostPick

WAIT SEC 0

;Reactivate the collision detection interrupt

INTERRUPT ON 25

;Reset the peak values

RESET_CM_MAX()

;Make sure the cycle flag is low before starting the motion

WAIT FOR NOT $CYCFLAG[255]

;Add this command if you want to resume the PickitSimplePicking() routine

RESUME

END

Note

Depending on which Pickit software version you are running, the program can look different, even though the functionality is the same. We recommend to use the program shipped with your Kuka connect version

Define the tool for picking

Create a tool with the actual TCP values. Make sure that the tool has the correct load data. In this program, #TOOL1 is used.

Set correct input arguments

The commands Pickit_configure and Pickit_detect_with_retr need input arguments.

See Pickit communication functions for more information about these arguments.

Define fixed points

In this program, 4 fixed points are used. These points need to be defined depending on the application.

Home: Where the robot will start the program.

Detect: Where to perform object detection from.

AbovePickArea: A point roughly above the pick area from which the above two can be reached without collision.

Drop: Where to place objects.

Pick sequence settings

The five-point extraction path can be modified with these four variables defined in the respective .DAT file:

PrePickOffset: the z-offset for

F_PrePickrelative to the tool frame.PostPickOffset: the z-offset for

F_PostPickrelative to the tool frame.binEntryZ: the z absolute value for

F_BinEntryrelative to the robot base.binExitZ: the z absolute value for

F_BinExitrelative to the robot base.

Add grasping/releasing logic

At the F_Pick and Drop points, grasping and releasing logic needs to be added, respectively.

Collision recovery

In KUKA, collision detection is used to monitor the axis torques. If one of these exceed a limit value, the robot stops and operator intervention is needed.

The general preconditions for collision detection are:

$IMPROVED_COLLMON == TRUE.$ADAP_ACC ≠ #NONE.The load data are correct.

Collision detection is necessary in bin picking applications to protect the robot and the picking tool.

However, to avoid production downtime, it is recommended to use a collision recovery strategy in the robot program during the Pick() subroutine.

This way, if the robot collides with an object during picking, the robot does not raise an error requiring operator intervention.

Instead, the robot goes back to the detection point and tries to pick another part.

Collision recovery is implemented in this program.

First, a set of torque sensitivities need to be defined in the respective .DAT file using the variables iSearchSensitivity[1], iSearchSensitivity[2], ... ,iSearchSensitivity[6].

These sensitivities should be lower than the torque limits defined in the enabled collision detection settings.

When one of these limits is crossed during the Pick() subroutine, a flag CYCFLAG[255] is raised, which stops the robot motion and calls the RetreatWhenFound() subroutine.

This will prevent the axis torques from reaching higher values that trigger a robot stop.

When the RetreatWhenFound() subroutine is executed, the application can be resumed by taking another detection and trying to pick again.

Execute the picking program

Attention

Before running the robot program for the first time, make sure that:

There exists a valid robot-camera calibration.

The Tool Center Point (TCP) has been correctly specified.

The robot speed is set to a low value, so unexpected behavior can be identified early enough to prevent the robot from colliding with people or the environment.

Pickit is in robot mode, which is enabled in the Pickit web interface.

Now you can run the program. Happy picking!