Warning

You are reading the documentation for an older Pickit release (2.3). Documentation for the latest release (4.0) can be found here.

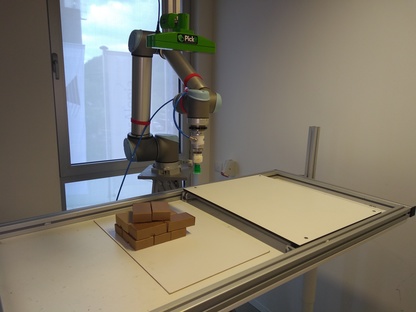

Pickit example case: Picking of randomly stacked boxes

In this article you will learn how to pick the cardboard boxes in the picture above with Pickit. We cover the basics of the application as well as the robot program used in this application. The result will be a working robot application to pick the boxes with a vacuum gripper and drop them off with exact orientation.

For this article we assume knowledge about the basics of Pickit Flex and Pattern. If you are not yet confident with these detection engines you can get up to speed by reading the following articles: Flex & Pattern

Motivation

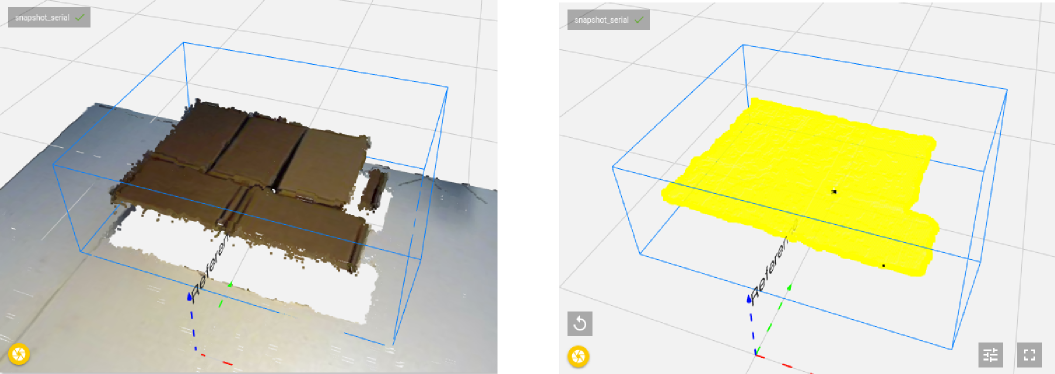

This application picks randomly stacked boxes. From the way they are presented it is hard to see the orientation of the boxes. As you can see in the image below: The 3D information shows one big surface. From the yellow plane it is a challenge to determine the exact location of all five boxes. Here we will discuss a method that is able to solve these kind of cases.

The idea to solve this case is to do this in two steps. In the first step the focus lies on isolating a part by picking it and dropping it on a new location. In the second step the system looks again to determine the orientation of the isolated box. After the orientation is determined the box is picked again and stacked in an organized way.

See video below for the result of this approach. Further below everything is explained in detail.

Advanced ROI filter: Dynamic Box-based ROI filter

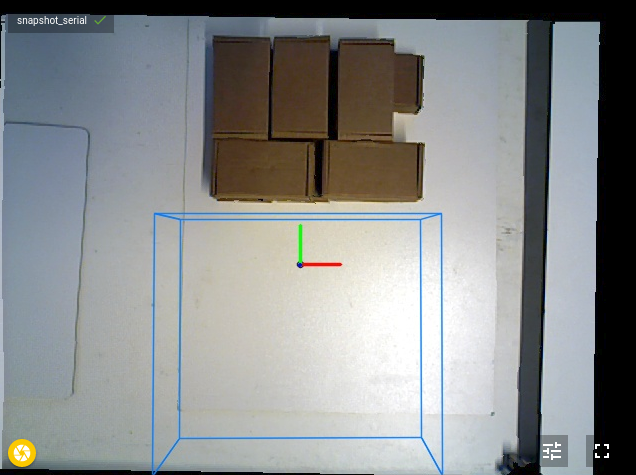

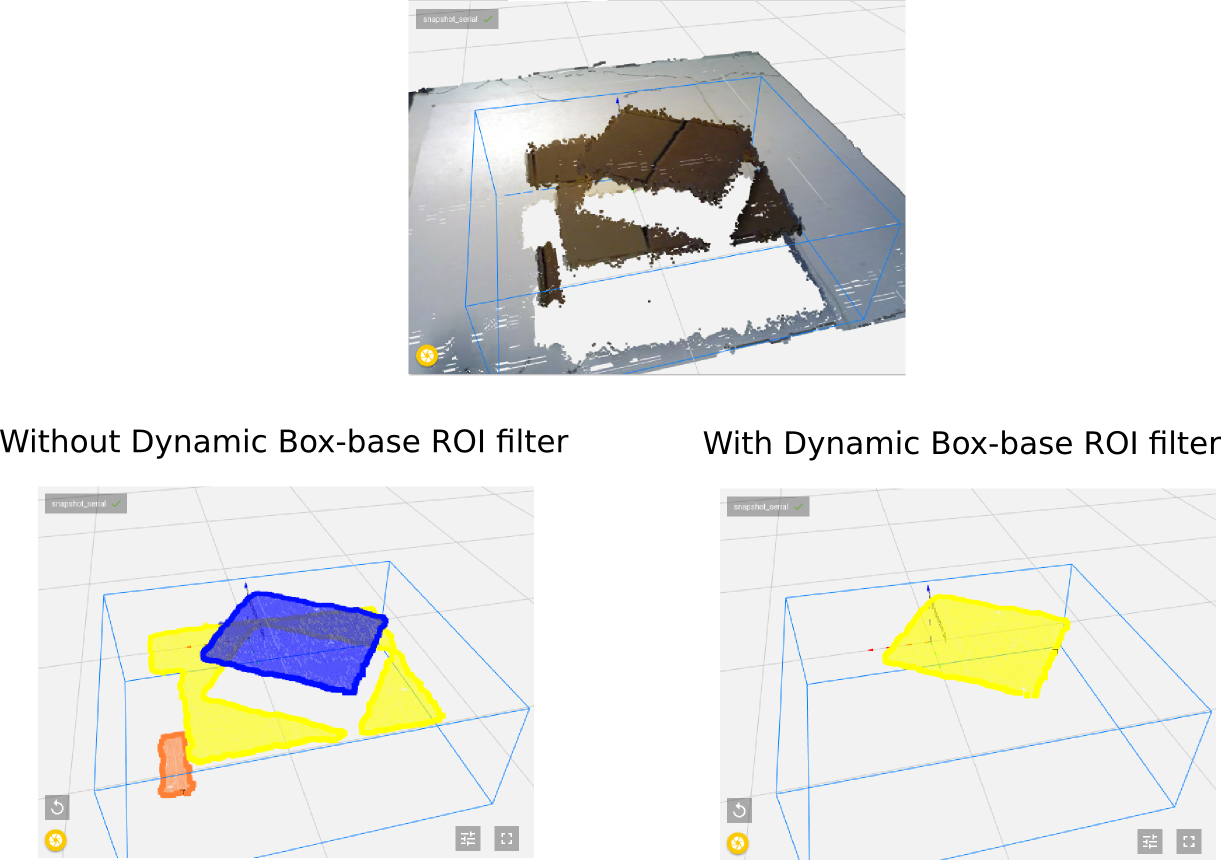

The boxes are stacked on a table in different layers. It seems logical that the robot should always focus on the top most layer first and afterwards proceed to the next layer. This is achieved by using the Dynamic Box-based ROI filter, which discards any points below a specified distance from the highest point in the Region of Interest (ROI). Below the effect of this filter is shown.

Only when all boxes in the top layer are picked, the next layer becomes visible in the Points view, since it now contains the highest points. For this application the system only keeps the points that are at most 20 mm below the highest point.

If you are interested in more information about our advanced ROI filters you can have a look a this article: Advanced filters.

Small plane strategy

In some applications it is hard to determine the correct orientation of parts when they are presented in a random way. To solve this kind of applications a two step method is applied. In the first step the only aim is to isolate a part. This is done by attaching our gripper to a part and to drop it somewhere isolated. For this first step it is not important where the gripper is attached to the part it should just be a good place where the gripper can attach himself.

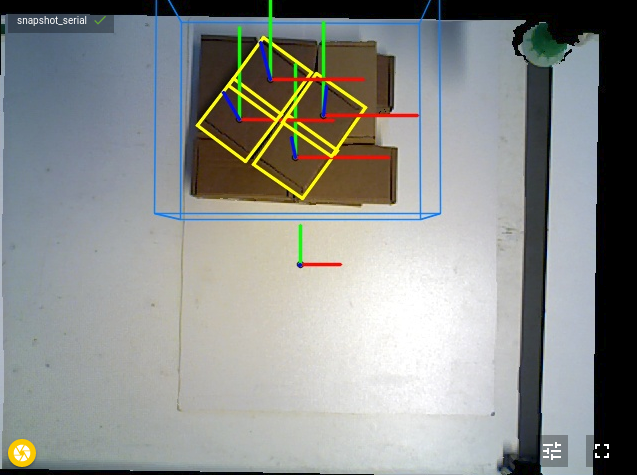

Here the application is solved by looking for squares with Pickit Pattern. The dimension of the squares that is looked for is the same as the width of the objects. By looking for these squares we know that each attachment point is found is always somewhere on the part. See image below to see how four different attachment points are calculated for the first layer (two for each box). The system does not look for the object as a whole but will look for small planes on the object good enough to attach himself to. This is what we call the small plane strategy.

Enforce alignment

In this first step the orientation of the part is from no importance. This means that the pick points can be forced to be orientated in exactly the same way. By using the option XYZ||XYZ all pick points will be orientated exactly as the reference frame. This allows further optimization of the movement speed of the robot, because the last wrist movement of the robot is not used. By applying this strategy it means that in the first step all parts will be picked and dropped with the same orientation.

Interested in enforce alignment? See this article about Enforce alignment of pick point orientation.

Robot program

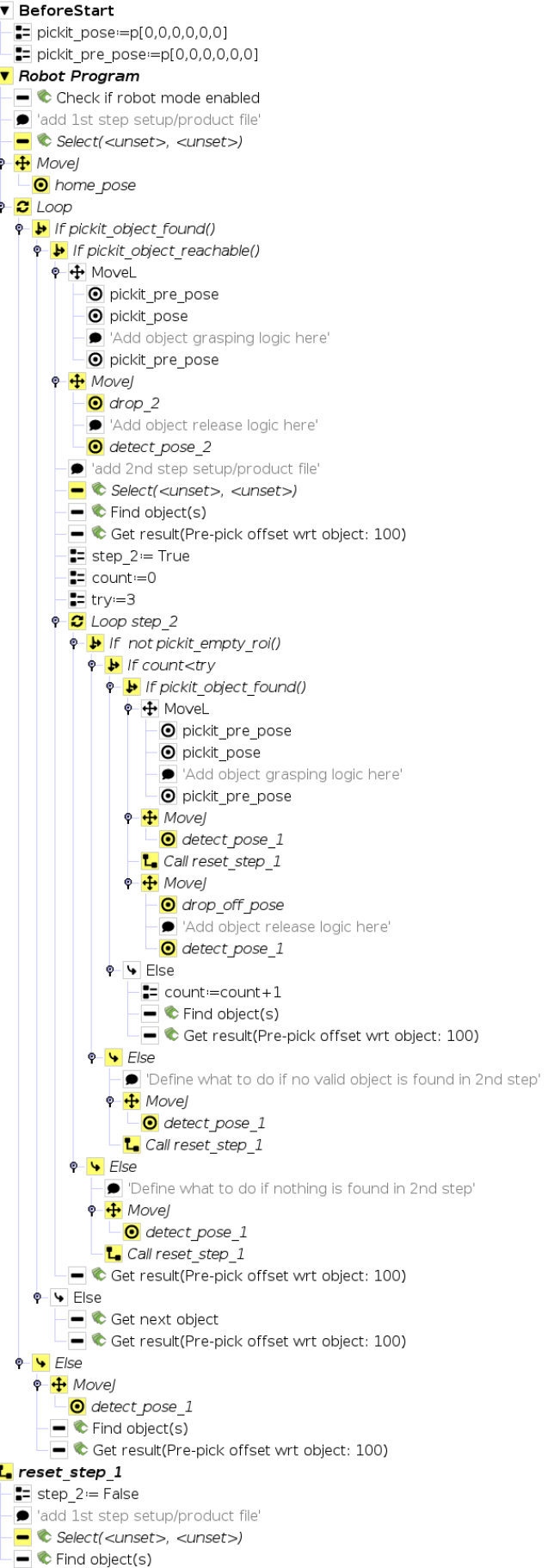

To set up this application, we provide the two-step template program, presented below. The template starts by first picking a box from the stack. The box is dropped in an isolated area and here the correct orientation is determined. Finaly the box is picked again and dropped in a pattern.

Below the image, all variables that need to be filled in the template are explained. The example program can be downloaded here.

First step

The start of the program is similar as the URCap example picking program. The waypoint drop_2 is where the box is dropped to trigger a second detection. The waypoint detect_pose_2 is defined so the robot doesn’t block the camera when triggering the second detection. In this application the grasping and release logic is turning on and off the vacuum.

Second step

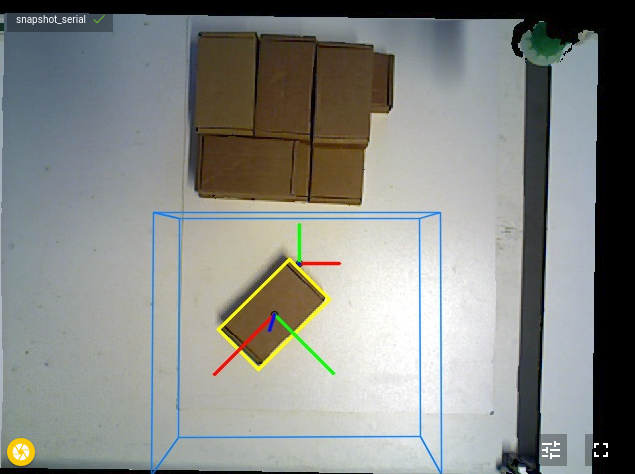

In the second step we start by selecting the correct setup and product file. Here the product file is a Flex detection looking for rectangles. The setup file is defined around the isolated area. Based on the detection triggered by Pickit multiple cases can be defined.

Valid object is found

If a valid object is found, the box is picked again. The robot passes by detect_pose_1 to be sure to not block a detection on the stack and immediately a new detection on the stack is triggered. In the meantime the box is dropped. For this application, the palletizing function of UR is used.

No valid object is found

In this template, Pickit tries multiple times to find an object. But if after n retries no valid object is found, you can define what to do. This means that there is something in the isolated area, but it is not the box that we are looking for. In this simple application this case never happened. But one can easily imagine that you would trigger a cleaning command for the isolated area.

No object is found

In the program, the pickit_empty_roi() function is used to verify if

there are contents inside the ROI (see Detecting an empty ROI box for more

details).

If the ROI is empty, the program goes back to the first step.

Snapshots

Below you can download three snapshots to see the settings that were used for this application.