How to chose the correct clustering preset

The clustering preset is an important parameter when using the Flex or Pattern detection engines. In this article an example covering different clustering methods is shown and discussed. This example should help you choose the correct setting for your application.

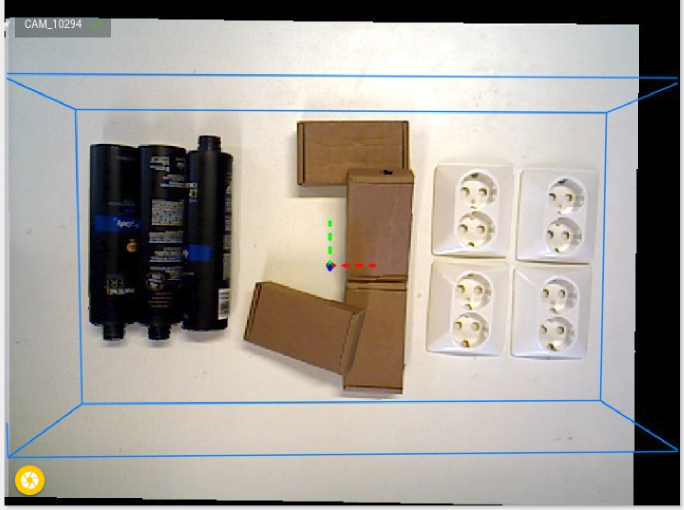

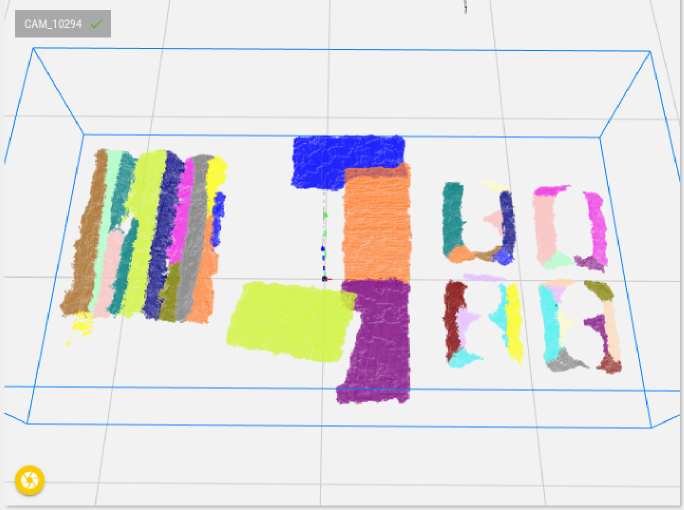

The scene below is used to explain the different clustering methods. In the scene there are three shampoo bottles next to each other, four boxes randomly on top of each other and four electrical plug shieldings separated from each other. A snapshot of this scene can be downloaded here.

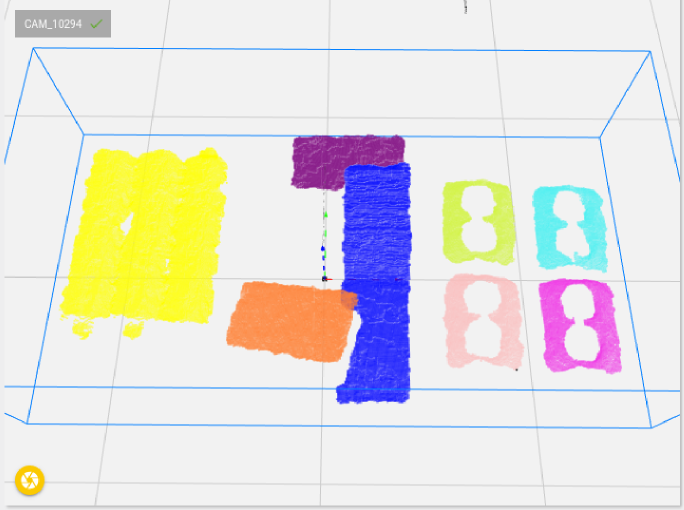

Touching parts

These methods look at the change of surface. If a surface change is too abrupt it is considered as a separate cluster. On the image below the results of this clustering method is shown. For the shampoo bottles three different clusters are formed which is good. For the boxes, the 2 boxes that are aligned but under an angle are not clustered apart. The transition of the surface is to smooth to filter them apart. For the electrical plug shieldings multiple clusters per part are formed, which is not good.

Best results for:

Rounded parts

Cylinders: bottles, gas springs, steel bars,..

Balls: tennis balls, oranges,..

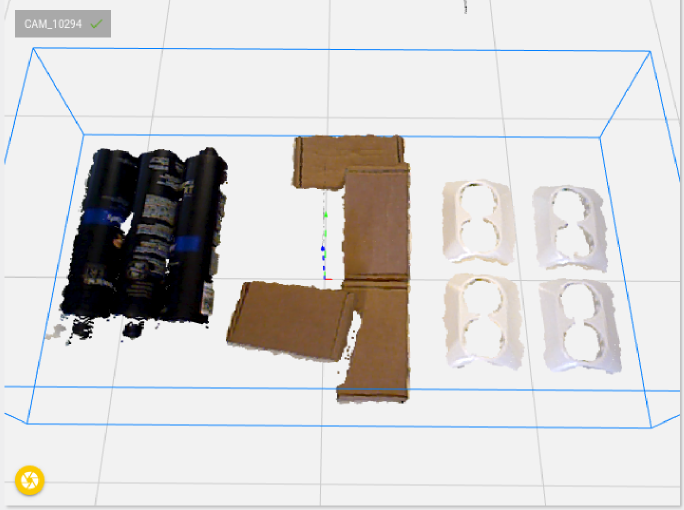

Plane Based Clustering

This method looks for flat surfaces in the scene. If two surfaces have a different orientation they are considered separate clusters. On the image below the results of this clustering method is shown. For the shampoo bottles multiple clusters are formed, which is not good. All boxes are clustered apart and no points are missing at the edges of the surfaces, which is good. For the electrical plug shieldings multiple clusters per part are formed, which is not good.

Best results for:

Flat surfaces

Boxes

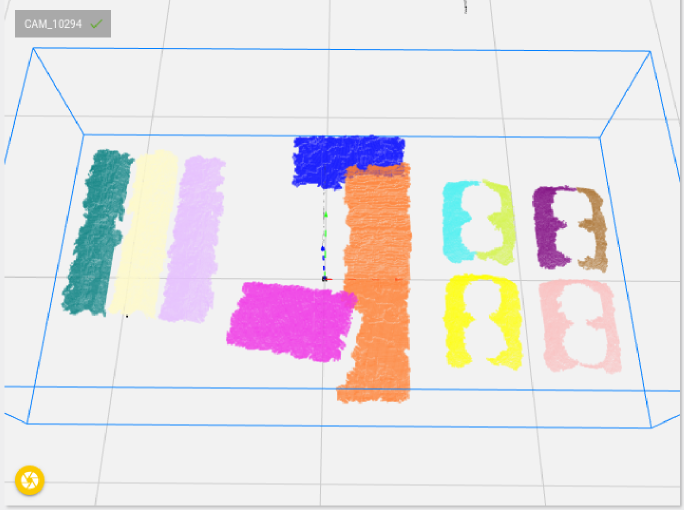

Non-touching parts

This method groups points into cluster that are close together. Objects are clustered apart if there is a physical gap. On the image below the results of this clustering method is shown. For the shampoo bottles one big cluster is formed, which is not good. Also the two aligned boxes are not clustered apart. For the electrical plug shieldings, which are positioned separated, one cluster per part is formed, which is good.

Best results for:

(Complex) non-touching shapes