Warning

You are reading the documentation for an older Pickit release (2.1). Documentation for the latest release (4.0) can be found here.

Build a showcase demo with a M-HD-Camera and two-finger gripper

This article will guide you in setting up a simple showcase demo with Pickit and a UR that you can show at trade fairs. For this demo a Pickit M-HD camera is used to detect cylindrical red parts in a bin. The parts are picked from the bin with a UR5 robot and a two-finger gripper. A video of the end result can be seen below.

Requirements

The list below shows the different hardware that has been used to set up this demo.

Pickit system with M-HD camera

UR5 robot

Stand to mount the robot and the camera on

On robot gripper RG2

Bin with size 400 x 300 x 120 mm

Cylindrical red parts (contact Pickit if you want to show this demo at a fair with these parts)

Mounting instructions

The robot and camera are mounted on a stand. The camera is mounted at a height of 700 mm above the work surface.

The two-finger gripper is mounted on the flange of the robot.

The bin is placed at a distance of 500 mm (center of robot base to center of bin) and is placed 40 mm lower than the robot base.

Setting up the Pickit files

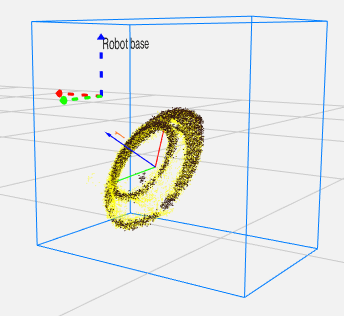

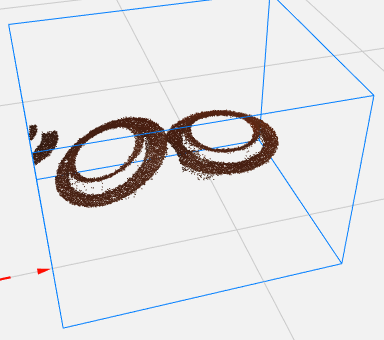

Here you can download a snapshot of the demo. In the snapshot, you can see that the parts are detected by using the Teach detection engine with 2 different models, namely one from the top side and one from the bottom side.

Setup file

For this demo the ROI box has similar dimensions as the real bin, except that it’s slightly smaller and higher. This will be important because the dimensions of the ROI box will be used for collision prevention. Last, the ROI box is attached to the Robot base frame. No other settings are used for this demo.

Need help with these settings? See the Region of Interest article for more information.

Product file

The models that are being used correspond to the shape of the top and bottom of the part. The difference lies within the height of both models. The pick frame of each model is put in the center. The matching score and tolerance is set to 85% and 1.8 mm. No downsampling is applied and the detection speed is set to Fast.

Need help with these settings? See the Teach article for more information.

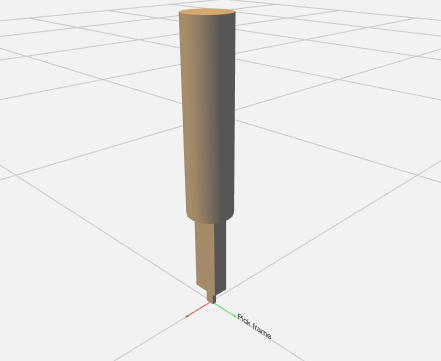

In the Picking page no alignments are enforced. For this demo, collision prevention is enabled. It is checked that the calculated pick frames are not steeper than 30 degrees. Also, collisions between the tool and the bin or other objects are checked. For this check it is important that a good tool model is defined. See below for the used model for the two finger gripper in the video.

Warning

Possible collision with the support of the camera is not checked.

Need help with these settings? See the Picking article for more information.

Calibration

Next step is the robot-camera calibration. This process teaches Pickit where the robot base is located w.r.t. to the camera. This information is used to transform the object pick-frames into robot coordinates. A detailed description in robot-camera calibration can be found in the article Calibration.

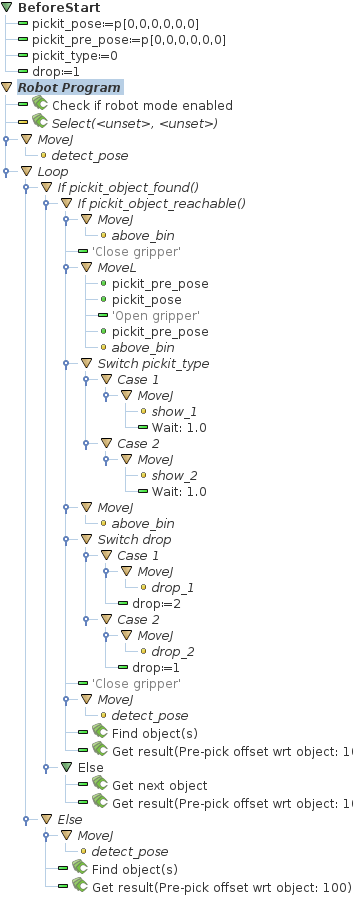

Setting up the robot program

Here you can download the UR robot program. The idea of the program is to pick one part. Depending on which side is picked (top/bottom) it is shown in a different way. After showing the part it is dropped back into the bin. The drop off position alternates between two predefined waypoints.

The following still needs to be defined in this robot program:

Pickit select command, the correct setup and product file need to be filled in.

The detect_pose is a waypoint defined outside the field of view of the camera, this is also the starting position of the program.

Above_bin is a fixed waypoint on the center top of the bin. This intermediate waypoint is used to get in to and to get out of the bin.

Before the robot will move in the bin the gripper is closed. Once the robot is in the pick pose the gripper is opened again to grab the parts.

Depending on which side is picked, it is decided how the part is shown. For this two different waypoints need to be defined. One position is upside down to show a clear difference on how the part has been picked.

After the showing of the part it is dropped back into the bin. Here the program alternates between two different drop off poses. One drop off position is defined on each side of the bin. After reaching the drop off position the gripper is closed to drop the part.

Interaction with the running demo

This demo is robust and will keep on working continuously. After a while it could be that the robot is unable to pick parts from the bin. This is due to the random positions the parts can have. For this reason it is advised to have some interaction with the demo.

Interaction with the scene is possible when the robot just picked a part and is showing it off. After a detection is triggered (flashing light) the scene can’t be changed anymore.

Parts can be placed under angles quite easily if you let them lean on each other. This will result in nice robot movements to pick these parts.

If parts are positioned on their side Pickit can still find them. But they are not send back to the robot because the calculated pick frame is to steep. If all parts would be dropped like this the robot will not be able to pick any part. That is why it is advised to have some interaction with the demo while it is running.