Object ordering

When multiple objects are detected, object ordering determines the order in which they should be picked. The following strategies are available:

Highest pick: Sort objects by their pick point location, from largest to smallest ROI frame Z-coordinate.

Highest object point: Sort objects by the highest detected point.

Largest product (Flex only): Objects are sorted from big to small volume or surface.

Highest matching score (Teach only): Sort objects with the highest model matching score first.

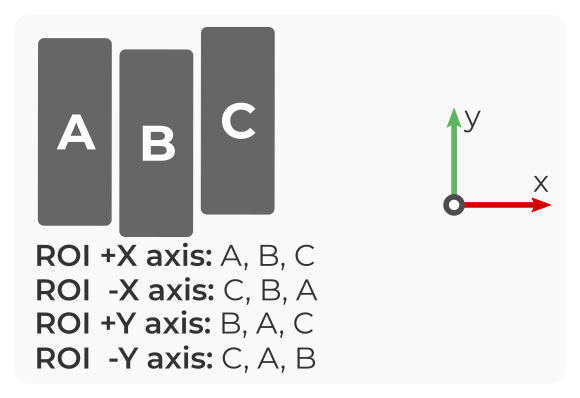

Axis Sweep: An axis sweep orders objects according to the value along the selected direction.

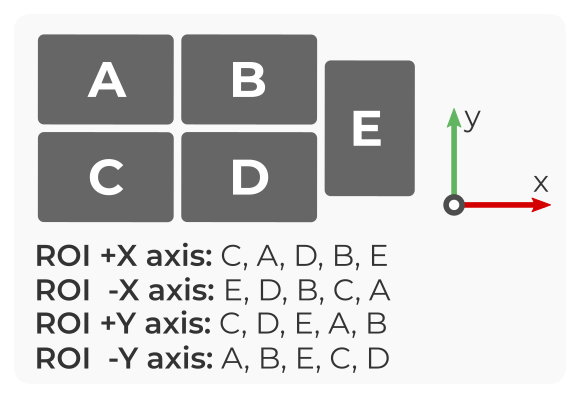

2D Pattern sweep: A 2D pattern sweep orders objects by performing a pattern that advances along the selected direction.

The Axis Sweep and 2D Pattern Sweep ordering strategies are useful for depalletization and other semi-structured picking applications.