How to get more pickable parts?

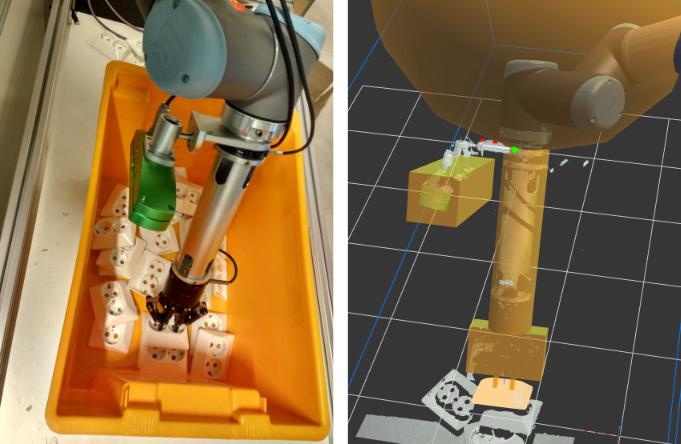

To successfully pick a part, it first needs to be detected, then a pick point must be selected. Constrained scenarios like bin picking are such that only limited regions of a part might be reachable for the robot tool to pick without colliding or violating other application constraints.

These guidelines cover the different aspects to take into account to get as many pickable parts as possible per Pickit detection run.

Tip

Before starting any optimization, we recommend you to learn what makes objects unpickable. This will help you make informed decisions about your application. To this end, the objects table provides details on whether an object is pickable, and if not, the reason why.

Note

Learn more about how the features from this article can be used in practice from the smart picking and smart placing examples.

Robot tool

The choice of robot tool plays an important role in enabling parts to be pickable. This is especially so in applications like bin picking, where parts are randomly oriented inside the bin, and the robot tool is subject to colliding with the bin or its contents during the picking motion.

Refer to the article on what makes a good tool for bin picking to learn more about what the best practices are in this respect.

Collision prevention

Pickit is capable of generating pick points where the robot tool doesn’t collide with the bin or its contents. To do so, you must do the following:

Model the robot tool, taking into account the best practices.

Enable collision prevention.

If the tool can collide with the bin, model the bin in the collision environment.

Pick points

A pick point represents where an object can be picked by the robot. If a part can be picked in different ways, it’s encouraged to specify multiple pick points in the model to increase the likelihood that, when detected, it will be pickable.

In addition to the tool-related considerations presented here, the following recommendations apply to specifying good pick points:

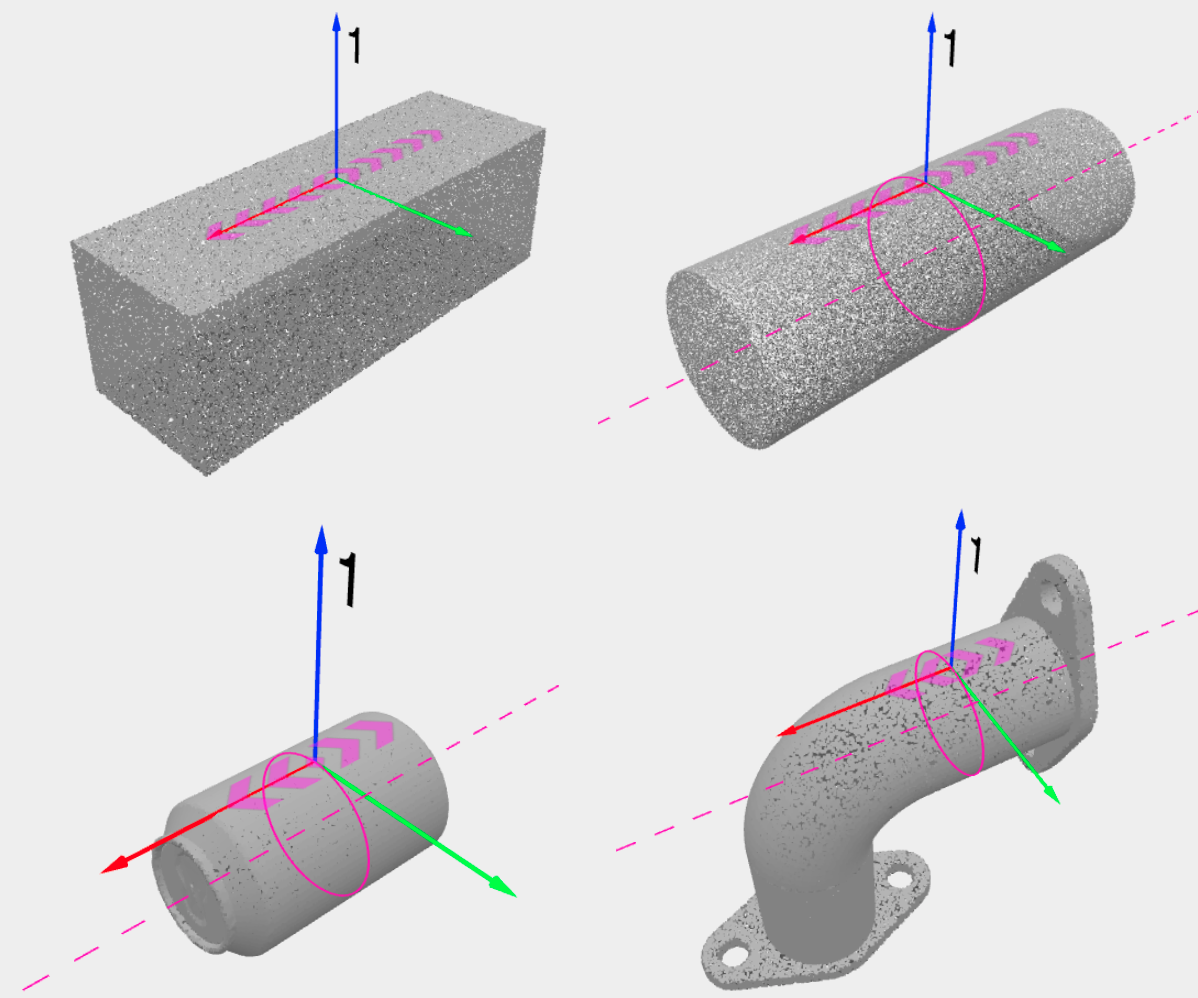

There should be pick points in every orientation the part can be presented to the camera.

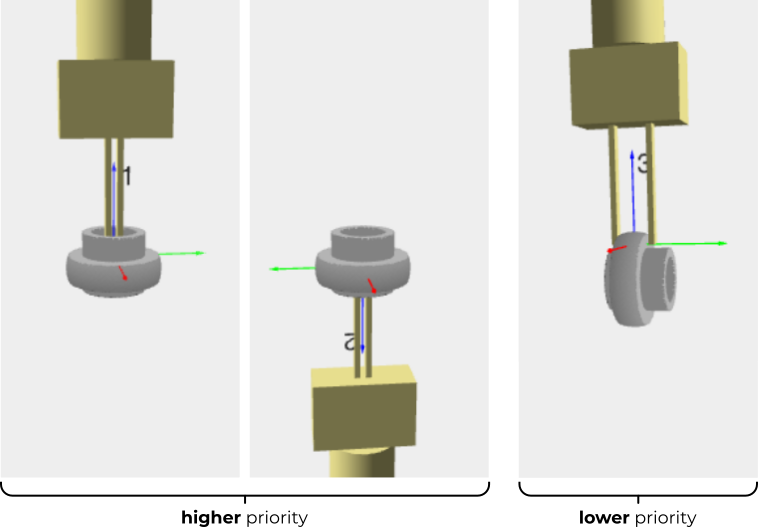

When multiple points are pickable at the same time, you can specify a preference of which to use by means of pick point priority.

When a pick point is symmetric about an axis, make this explicit.

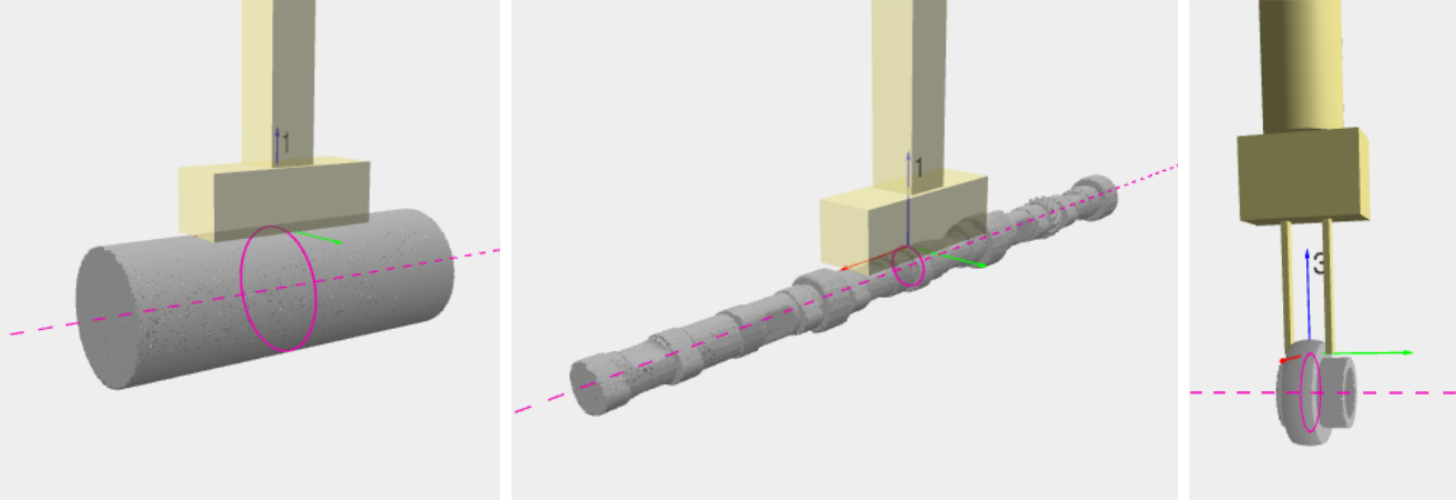

When a pick point tolerates position variations along a direction, use flexible pick position.

If you have tight pick accuracy constraints, prefer teaching your part model from CAD (or from a primitive shape like a cylinder or box). If the origin of the CAD model is known with respect to the part geometry, pick points can be positioned by specifying exact offsets with respect to it.

Pick strategy constraints

As part of the picking strategy, Pickit exposes the following settings that, if set too strictly, can limit the number of pickable objects. Make sure they are set to reasonable values for your application: